8 biggest construction problems in 2026: Fully explained

By

Marketing Team

@Onetrace

Across Europe, construction remains a vital part of the economy, accounting for more than 5% of total value added. Yet in recent years, output has edged down in many countries, with the UK seeing a 19-month low in November 2025.

These figures aren’t the result of a single cause, though.

They point to a set of long-standing problems that continue to weigh on the industry year after year.

With 2026 expected to bring many of the same pressures, it’s worth taking a closer look at what the eight biggest construction problems are, how they affect day-to-day work on site, and what can realistically be done about them.

Key takeaways

People shortages are the biggest construction problem

The lack of skilled workers affects productivity, quality, and supervision across every project. While no single business can fix the labour gap, investing in training, mentoring, and better use of existing teams can soften the impact and protect delivery.

Unpredictable costs matter more than rising costs

Material prices aren’t just higher; they are harder to plan around. Month-to-month volatility creates budget uncertainty, procurement delays, and margin pressure. Managing this risk depends on early decisions, sensible buffers, and tighter tracking of what is actually used on site.

Poor systems amplify everyday problems

Uneven technology use, fragmented communication, and manual processes lead to repeated work, missed information, and slow decisions. Simple, site-ready systems that are easy to adopt make a measurable difference to coordination and control.

Cash flow, safety, and compliance are closely linked

Late payments, safety incidents, and missed regulatory updates all increase risk and disrupt work. Treating these as daily operational issues rather than admin tasks helps reduce knock-on effects such as delays, disputes, and lost capacity.

The biggest gains come from controlling what you can

Labour markets and material prices are outside your control, but visibility, records, and coordination are not. Tools like Onetrace help subcontractors manage compliance, workforce activity, and proof of work in one place, making it easier to stay organised, get paid, and keep projects moving.

1. There aren’t enough people to do the work

The shortage of skilled workers remains the single biggest construction problem in 2026.

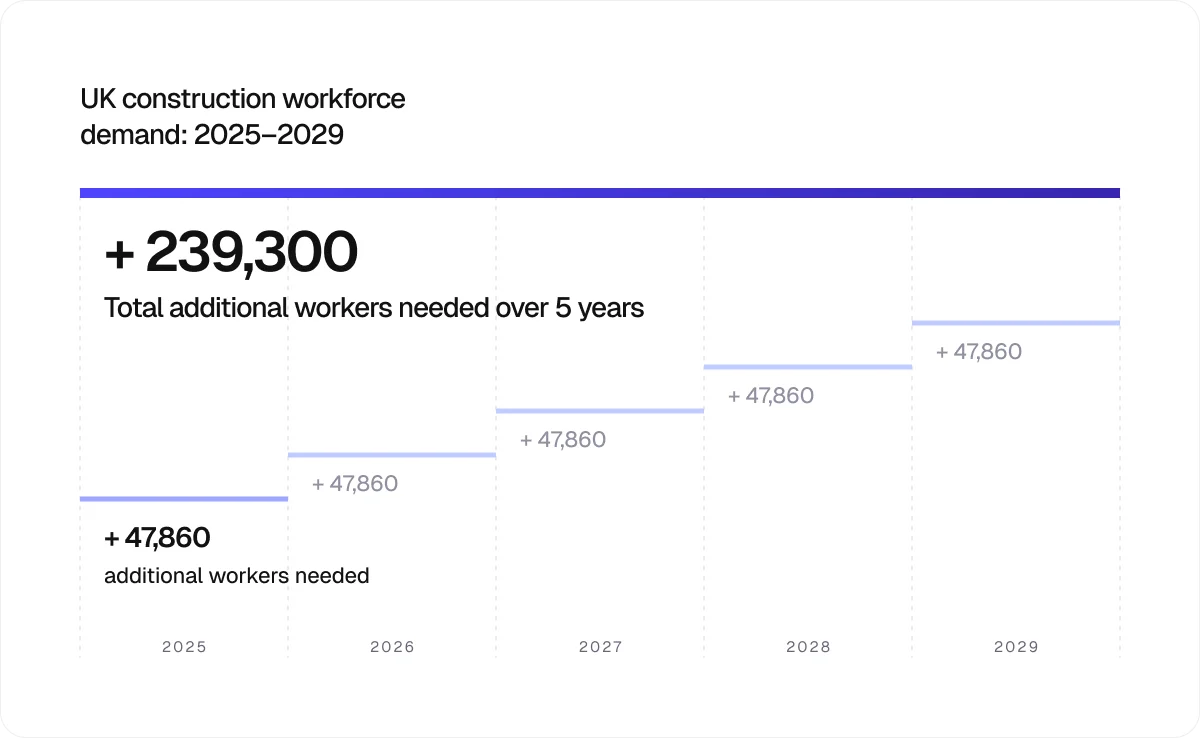

In the UK alone, the industry needs to recruit almost 48,000 additional workers per year just to meet expected demand.

The problem with achieving this goal is that not enough new faces are entering construction, as young people are increasingly being pushed towards university instead of vocational training, and trade work is often seen as unstable.

At the same time, a large share of the current workforce is approaching retirement, taking years of experience with them. Their skills, judgement, and site knowledge are hard to replace quickly, leaving gaps that affect productivity, quality, and on-site supervision.

Although individual businesses can’t solve this issue on their own, they can reduce the impact by:

Investing in apprenticeships and mentoring to pass on skills before workers leave the site

Working with colleges, training providers, and staffing partners to widen recruitment channels

Using construction management tools to make better use of existing labour

2. Material prices won’t sit still

Construction material prices rose by 3.3% in 2025 and now stand at more than double their 2005 levels.

What makes this construction problem even more difficult to manage is the unpredictability of pricing, not just the overall upward trend.

Prices for key materials such as steel, timber, concrete, and copper can shift month to month, often with little warning. This volatility is driven by fragile supply chains, changing trade rules, and shorter price-lock periods imposed by suppliers who want to protect their own margins.

On site, these changing prices lead to budget uncertainty, delayed procurement, redesigns, and margin erosion as assumptions made at tender no longer hold.

To reduce the impact, construction businesses should:

Identify high-risk materials and secure prices early

Price in sensible buffers for materials with known volatility

Leave room to adjust procurement timing and suppliers as markets shift

Use material-tracking tools to reduce waste

3. Technology isn’t used evenly

Construction has long been considered the least digitised sector in Europe.

Although steady effort is being made to improve digital work, the adoption rate remains uneven and under 50% overall.

Some parts of the industry now use BIM, digital scheduling, and real-time cost tracking, while many teams still rely on PDFs, spreadsheets, and manual updates.

This gap exists for a few reasons.

Technology budgets are often limited, systems don’t always work well together, and site teams are sometimes expected to use complex tools without enough training. The lack of technological support results in friction between the office and the site, duplicated work, missed information, and slow decision-making.

To avoid these outcomes, businesses should:

Invest in tools that are easy to pick up and use

Train site teams properly before rolling out new software

Standardise tools across projects to reduce confusion

Pro tip:

When introducing a construction management platform, look for tools that are built around how contractors and subcontractors actually work, not how software teams think they should work.

Tools like Onetrace focus on everyday realities, such as compliance, documentation, workforce coordination, and site reporting, with a simple interface that doesn’t assume people are tech-savvy.

When software is designed with the end user in mind and backed by a straightforward onboarding process and helpful customer support, adoption becomes far easier, and the gap between office and site starts to close.

4. Cash flow is tight

Cash flow remains a constant pressure for construction businesses, even on profitable jobs.

Companies must pay wages, suppliers, and subcontractors regularly, while payment for completed work often arrives late and in large, infrequent chunks. Higher interest rates and tighter access to credit only add to the strain.

As a result of this payment mismatch, construction businesses are forced to carry costs longer than planned, increasing their exposure to risk and limiting their ability to take on new work.

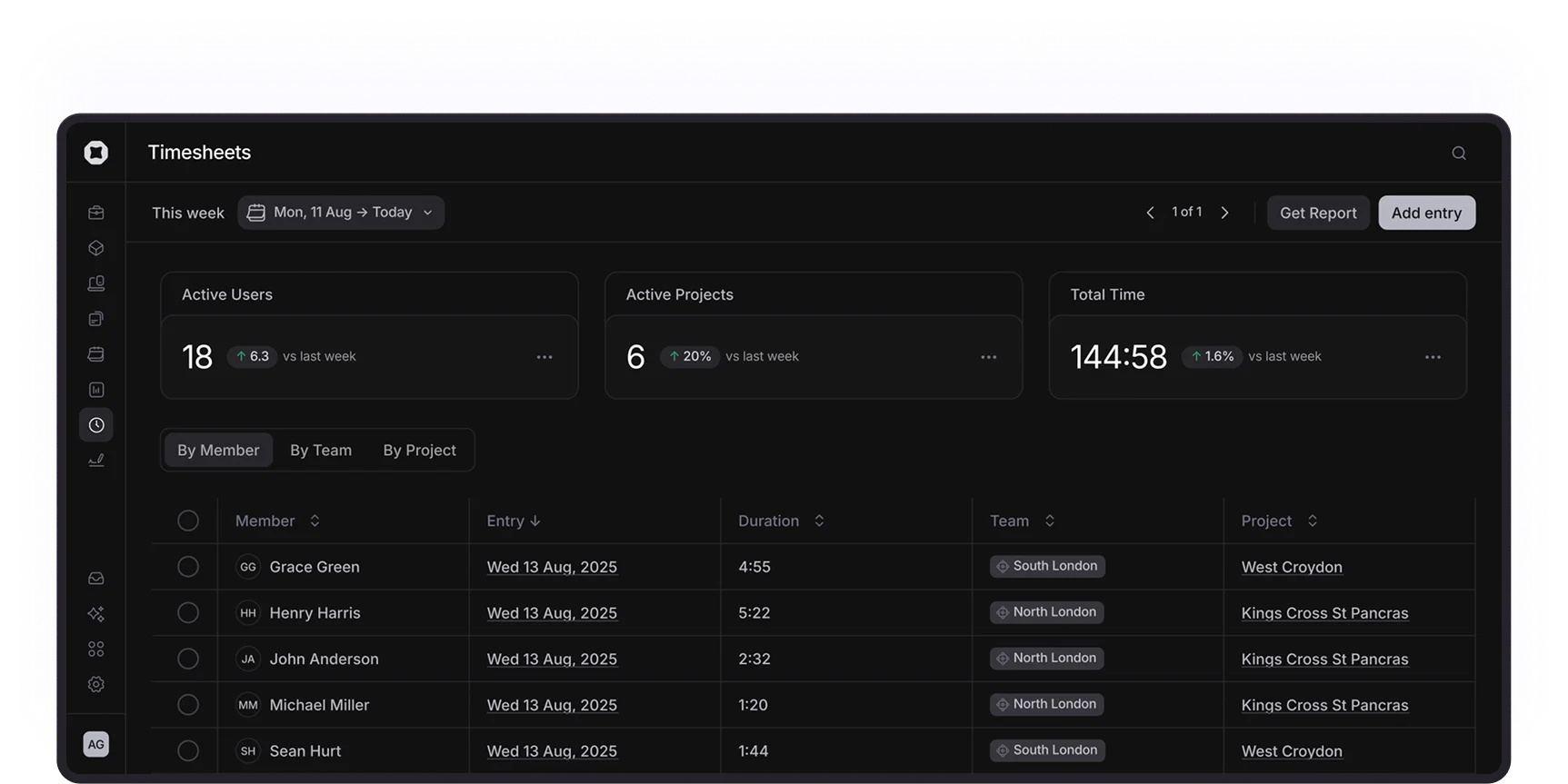

Steps that make a difference in easing this pressure include:

Planning cash flow conservatively, not optimistically

Using clearer payment schedules and tighter cost tracking

Automating invoicing and payment processes where possible

5. Rules keep changing

Construction is one of the most tightly regulated industries in Europe, and for good reason. Straightforward rules around safety, quality, and environmental standards protect workers, building users, and the public.

The challenge is adjusting to how quickly compliance requirements can evolve.

In England, for example, in late January 2026, the Building Safety Regulator expanded its remit and was brought into a single construction regulator, reflecting a wider move towards more consolidated oversight. Changes like this can have real implications for construction businesses, particularly regarding regulatory clarity, compliance expectations, and accountability.

When updates are missed or misunderstood, projects risk failed inspections, permitting delays, rework, or stoppages.

To avoid these scenarios, construction firms should consider:

Assigning direct ownership for monitoring changes

Centralising compliance information

Engaging with regulators before issues reach the site

Pro tip:

When compliance is part of daily site work, regulatory changes are far less disruptive. Instead of forcing a reset, they only require minor adjustments to existing processes.

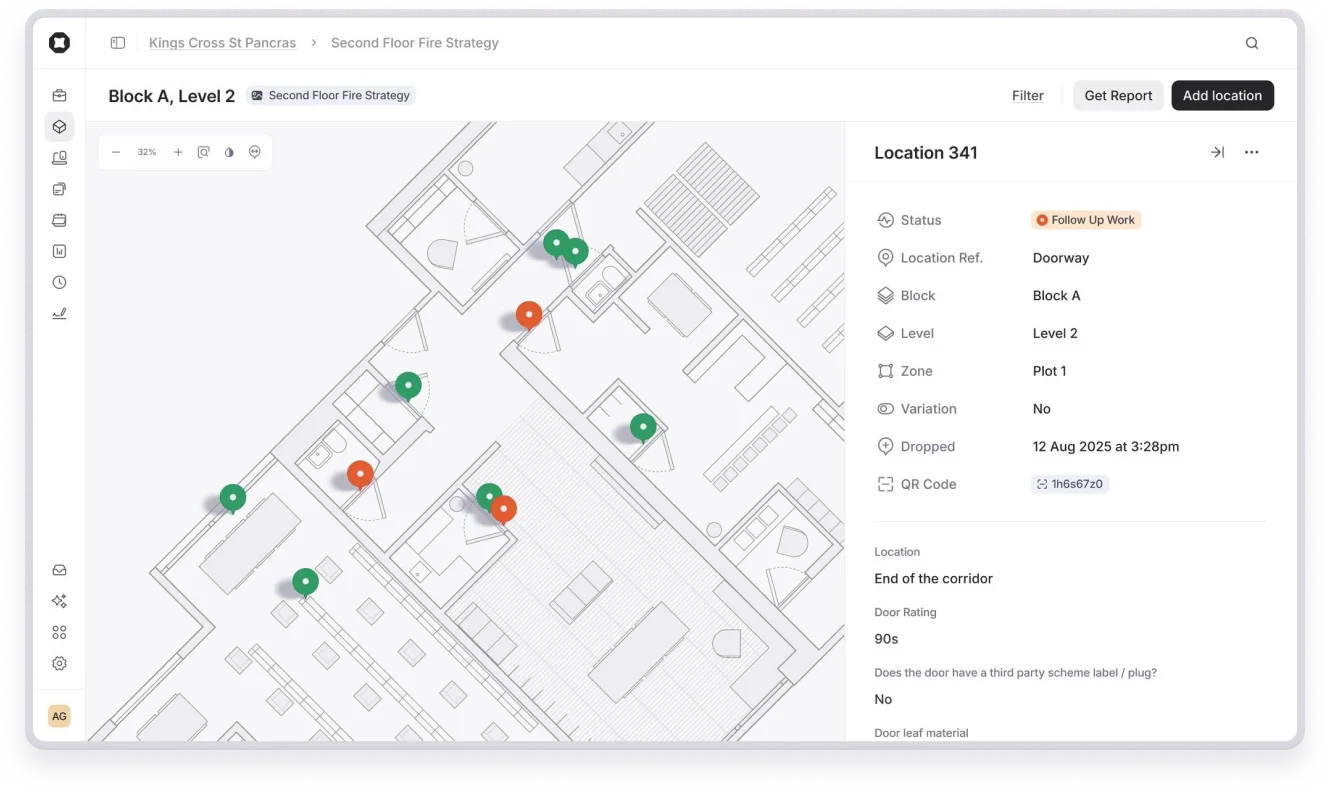

Besides serving as a central record for certificates, drawings, risk assessments, and compliance documents, Onetrace embeds compliance into everyday operations through features like:

Structured data fields to capture critical details, from installation methods to material specifications

Pre-configured materials and processes aligned with manufacturer and regulatory requirements, supporting traceability and accurate costing

QR codes on site to quickly check what was installed, where, and by whom

Certification tracking to show workforce competence and readiness across trades

Timesheets and site records that support health, safety, and audit requirements

6. Construction is a high-risk job

Safety compliance is a core part of construction compliance, but its importance goes beyond rules and paperwork.

Construction remains far more dangerous than most other industries, with a fatal injury rate almost five times higher than the all-industry average.

Failures in this department also bring knock-on effects, including:

Disrupted programmes

Lost skills on site

Lower morale

Higher insurance costs

Increased scrutiny from clients and regulators

Managing these risks works best when safety is part of everyday site activity, not something handled after an incident. This approach includes:

Consistent site induction and task briefings

Accurate records of who is on site and what they’re doing

Up-to-date training and competency tracking

Simple systems for reporting issues before they become incidents

Regular safety checks

7. Programmes rarely run according to plan

Staying on schedule is a challenge on almost every construction project, regardless of size or experience.

Even the UK’s £4.8-billion Levelling Up Fund struggled to stay on track, with a government review finding that 95% of its projects were running late, with many delayed by more than a year.

These issues usually start early, during the planning and scheduling phases.

Programmes are often built on optimistic assumptions, overlapping design and construction, and late procurement. Manual scheduling and constant ‘fast-track’ expectations leave little room for change when costs rise or information is incomplete.

On site, poor scheduling leads to rework, stop-start progress, stressed teams, and disputes when deadlines slip.

Businesses can take various steps to avoid scheduling issues, including:

Building programmes from realistic information

Reviewing schedules regularly instead of relying on static timelines

Using digital scheduling tools to track progress and adjust plans as conditions change

8. Communication breaks down too easily

Given how fragmented construction projects are, it shouldn’t be surprising that communication problems are common.

Most jobs involve multiple trades, shifting teams, tight timelines, and a constant flow of changes. Add separate office and site teams, different systems, and heavy reliance on emails, calls, and PDFs, and information is easy to miss or misinterpret.

Poor communication shows up quickly on site.

Work gets repeated, details are missed, and small issues turn into delays or disputes because people are working from different versions of the truth. When problems arise, the lack of clear records can also lead to finger-pointing instead of fixes.

Solving communication issues requires reducing fragmentation and making information easier to share and track by:

Keeping project information in one shared place

Establishing a standardised communication framework

Linking communication to drawings, locations, or tasks

Maintaining reliable records that show who decided what and when

Focusing on what’s within your control

Using construction management software like Onetrace can’t fix labour shortages, stabilise material prices, or remove supply-chain risk. However, it can make a real difference regarding the construction problems within your control: compliance, visibility, coordination, and workforce management.

‘Control’ is the key word when discussing Onetrace’s capabilities, as this software is designed to help businesses stay on top of the details that shape day-to-day performance, including:

What work has been done

Who did it

Where it happened

Whether it meets the required standards

This level of oversight is possible thanks to two distinct products: Traceability, which builds a compliant digital record of work, and Workforce, which helps manage people, time, and attendance more effectively.

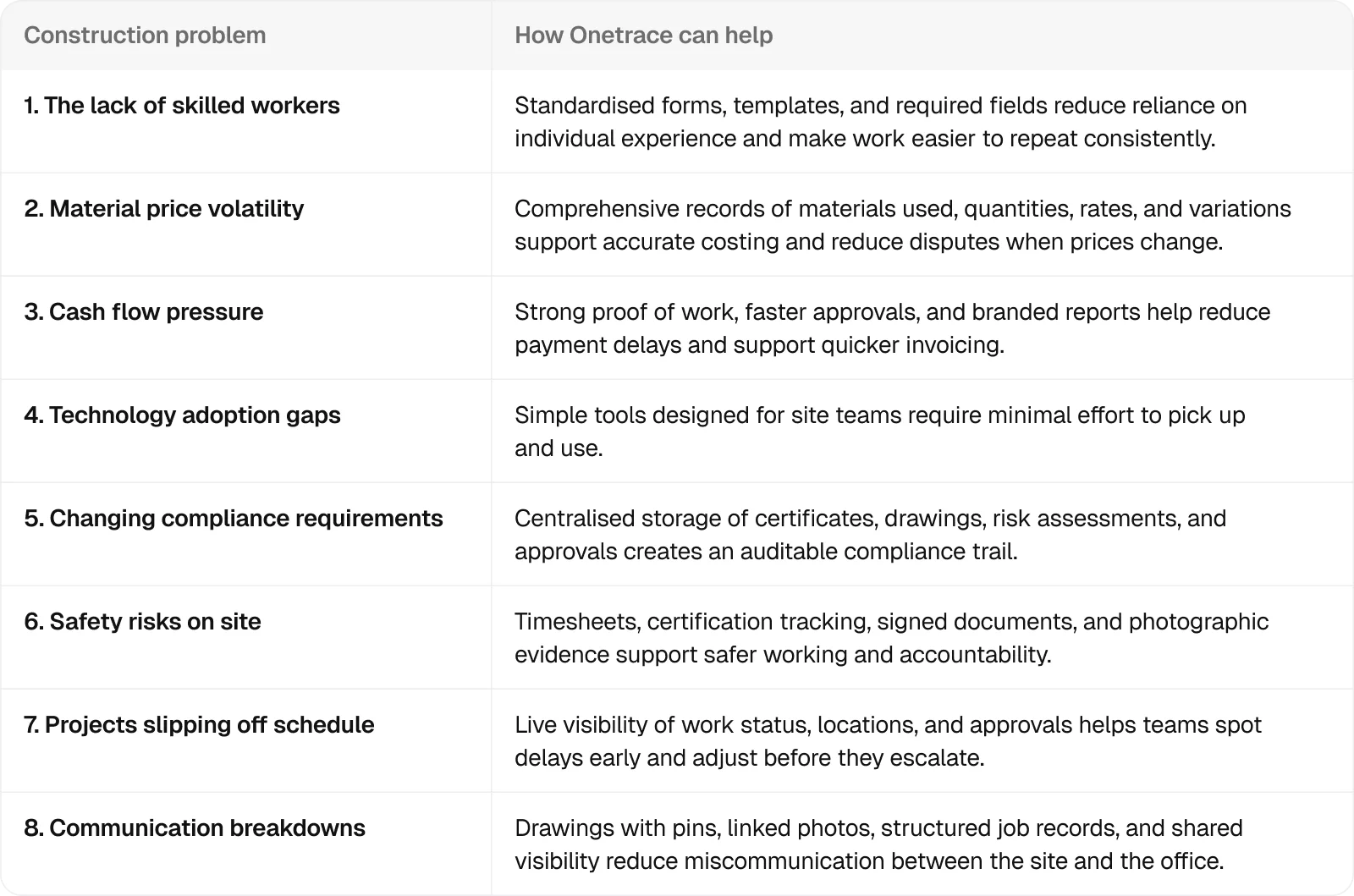

Together, these products can help solve, or at least reduce, the impact of the prevailing construction problems. The table below gives a practical snapshot of how:

If the construction problems in this article feel familiar, book a personalised demo with the Onetrace team to see how this platform can help you manage them better on live projects.

FAQ

What are the problems in construction?

Construction faces a mix of long-running and structural challenges. The most common are labour shortages, unstable material prices, tight cash flow, changing regulations, safety risks, scheduling delays, and poor communication between the site and the office.

What is the biggest issue in construction?

The biggest issue is the shortage of skilled workers. Too few people are entering the industry, while experienced workers are retiring faster than they can be replaced. This puts pressure on productivity, quality, safety, and schedules, and makes many other problems harder to manage.

Marketing Team

@Onetrace

The Onetrace marketing team is passionate about sharing insights, ideas, and innovations that help construction businesses stay connected, compliant, and efficient. Combining industry expertise with a love for clear communication, we aim to deliver content that empowers professionals to work smarter and safer.