10 ways to avoid construction scheduling issues in 2026

By

Marketing Team

@Onetrace

In construction, the average cost overrun sits at around 28%. On a project valued at £2 million, that can mean an extra £560,000 by the time the job is finished.

Although few clients are ready for that conversation, this isn’t a rare occurrence.

Between 2003 and 2018, 46.1% of construction projects in the UK ran over budget, with 42.1% finishing late. And that was before the pandemic, supply chain shocks, and rising labour pressure made scheduling even harder.

All of this makes one thing clear: poor construction scheduling comes at a high cost.

With that in mind, let’s look at 10 practical ways to avoid construction scheduling issues and keep projects moving as planned in 2026.

Key takeaways

Strong schedules start with proper planning

Most delays begin long before work starts. A clear schedule built around a defined scope, task sequencing, and real project data gives everyone direction and prevents confusion, rework, and early slippage.Realistic deadlines protect both teams and clients

Schedules based on optimism rarely survive contact with site reality. Deadlines that reflect actual task durations and team capacity reduce burnout, improve quality, and keep client expectations grounded.Resources must be allocated deliberately, not assumed

People, materials, and equipment are finite. When they aren’t aligned with the programme, work stalls or costs rise. Thoughtful resource planning keeps work moving and avoids bottlenecks between trades.Early action and contingency planning keep you in control

Supply chains, permits, weather, and labour availability are ongoing risks. Starting early and building contingency into the schedule gives you more time and information to make better decisions.The right technology ties everything together

Tools like Onetrace turn planning into day-to-day control. By combining live scheduling, timesheets, material tracking, compliance, and real-time visibility, Onetrace helps subcontractors stay ahead of delays rather than reacting to them after the fact.

1. Start with a detailed project schedule

Creating a well-thought-out schedule to avoid construction scheduling issues isn’t a revolutionary idea. A detailed schedule is the foundation for everything else. It should clearly define the project scope, break the work into manageable tasks, and map out how those tasks depend on one another.

Yet 38% of construction delays still come down to poor planning. If activities aren’t properly analysed or sequenced, timelines quickly become guesswork, and that’s when delays creep in.

Good schedules are built using real data, not assumptions. Looking at past project performance helps teams plan with clearer timelines and fewer surprises once work begins.

Get this right, and you’ll avoid:

Work starting out of sequence

Crews waiting on unfinished tasks

Confusion over what comes next

Delays that snowball into cost overruns

2. Set deadlines you can stand behind

A well-built schedule shouldn’t be a best-case scenario. When you build timelines on optimism rather than evidence, tasks get underestimated, small delays stack up, and pressure spreads across the job.

That’s why it’s crucial to be realistic about how long tasks actually take and how much work your team can genuinely take on at once.

Taking a realistic approach helps you avoid:

Missed deadlines and constant reprogramming

Rushed work and quality issues

Overloaded teams and burnout

Frustrated clients chasing updates

Delays that ripple across other trades

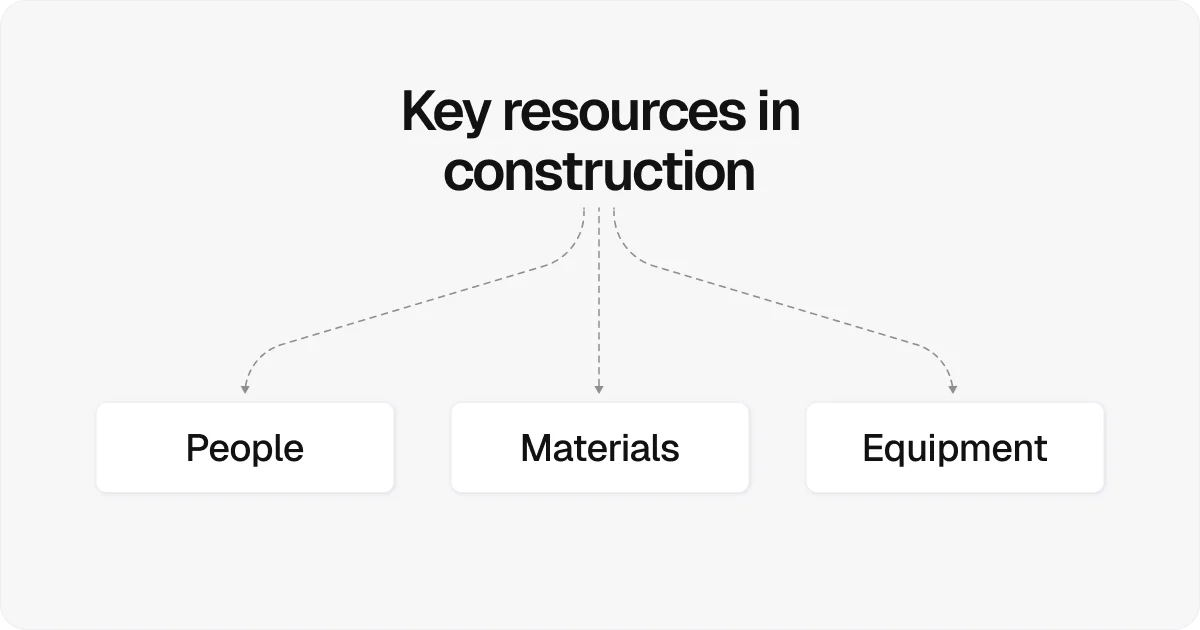

3. Make sure the right resources are available

Your construction schedule isn’t a board game. You’re not moving tokens around a chart; you’re coordinating real people, real materials, and real equipment.

The only way to avoid construction scheduling issues is to allocate those resources deliberately, not assume they’ll be available when needed.

In practice, this means assigning tasks to people with the right skills, balancing workloads so crews aren’t stretched thin, and making sure equipment and materials align with the programme.

Good resource planning keeps work flowing and gives you options when conditions change.

This approach helps prevent:

Crews waiting with nothing to do

Equipment sitting idle or being double-booked

Bottlenecks between trades

Overtime and rush costs

Delays caused by simple availability gaps

4. Act early to stay in control

Whatever you can start early, you should, because your options narrow fast once the project is live. Take supply chains as an example—66% of European construction professionals report supply chain delays, and 64% say those delays increase costs.

Materials, permits, inspections, and subcontractor availability all take longer than they used to. Starting early doesn’t remove that risk, but it gives you room to manage it.

Below is a breakdown of common issues you can reduce by acting early:

Issue | What to start early | What you avoid |

Material availability | Ordering key materials with extended lead times | Crews waiting on site |

Long lead items | Sharing date-needed info well in advance | Programme gaps |

Subcontractor shortages | Securing trades months ahead | Missed handovers |

Permits and inspections | Submitting applications | Forced downtime |

Labour shortages | Recruiting before site mobilisation | Last-minute reshuffles |

5. Build contingency into your schedule

In construction, you have to plan for the unplanned. There are too many things that can throw a job off course: weather turning, materials stuck in transit, permits delayed, labour shortages, or a supplier failing to deliver.

Because these are common risks, every schedule needs a clear contingency plan. That means identifying the most likely causes of delay and deciding in advance how you’ll respond.

Good contingency planning covers buffer time in the schedule, backup suppliers or materials, flexibility in resource allocation, and clear steps for adjusting timelines when something goes wrong.

Putting contingency plans in place helps you avoid:

Panic-driven schedule changes

Work stoppages during delays

Costly last-minute decisions

Knock-on delays across trades

Damage to client confidence

6. Set clear expectations with everyone involved

Building a solid foundation with the people you work with is just as important as building a solid construction schedule. That includes your own crew, subcontractors, suppliers, and clients.

When relationships are strong, communication is clearer, problems surface earlier, and issues are easier to resolve before they affect work.

However, while solid relationships help, they’re not always enough. After all, everyone is juggling pressure, workloads, and competing priorities.

That’s why clear contracts matter. Written expectations protect timelines when goodwill alone can’t. The table below outlines clauses worth including in your contracts to prevent unexpected delays:

What clause to include | Which party it aims | What it does | What it prevents |

Delivery incentives and late penalties | Suppliers | Rewards on-time delivery and applies agreed costs if materials arrive late | Material delays |

Mandatory progress updates | Suppliers | Requires regular updates on order status and potential delays | Surprise shortages and last-minute changes |

Time of completion | Subcontractors | Sets clear start and finish dates tied to the programme | Missed start dates and trade clashes |

Liquidated damages | Subcontractors | Agrees on cost per day if work finishes late due to their delay | Schedule overruns and knock-on delays |

Clear scope and payment terms | Teams | Defines responsibilities, outputs, and when payments are made | Disputes, slow decisions, and loss of focus |

Timely approvals clauses | Clients | Sets deadlines for reviewing and approving designs or changes | Delays caused by slow client decisions |

7. Keep communication open and consistent

Clear communication on and off site is essential to keeping a construction schedule on track. When information is late, unclear, or shared with the wrong people, small issues turn into delays fast.

But good communication means more than the odd update. It relies on regular check-ins, clear points of contact, and shared systems where everyone can see progress, changes, and decisions.

Assigning responsibility avoids confusion, while prompt updates, especially when something goes wrong, give teams time to respond instead of react.

When communication is treated as part of the schedule, not an afterthought, it helps avoid:

Crews turning up at the wrong time

Conflicting instructions on the site

Delayed decisions and approvals

Clients being caught off guard

Issues escalating before they’re addressed

8. Educate your team on scheduling

Everyone on the job influences the schedule, whether they realise it or not. When teams understand how the schedule works—and how their actions affect others—fewer mistakes happen.

But education doesn’t mean long training sessions.

It means showing people how to use shared scheduling tools, where to find up-to-date information, and who to speak to when something changes. Clear protocols for updates, handovers, and issue reporting help keep work aligned across the site and office.

When teams are properly briefed, you reduce:

Missed handovers

Conflicting information

Rework caused by misunderstandings

Delays triggered by simple errors

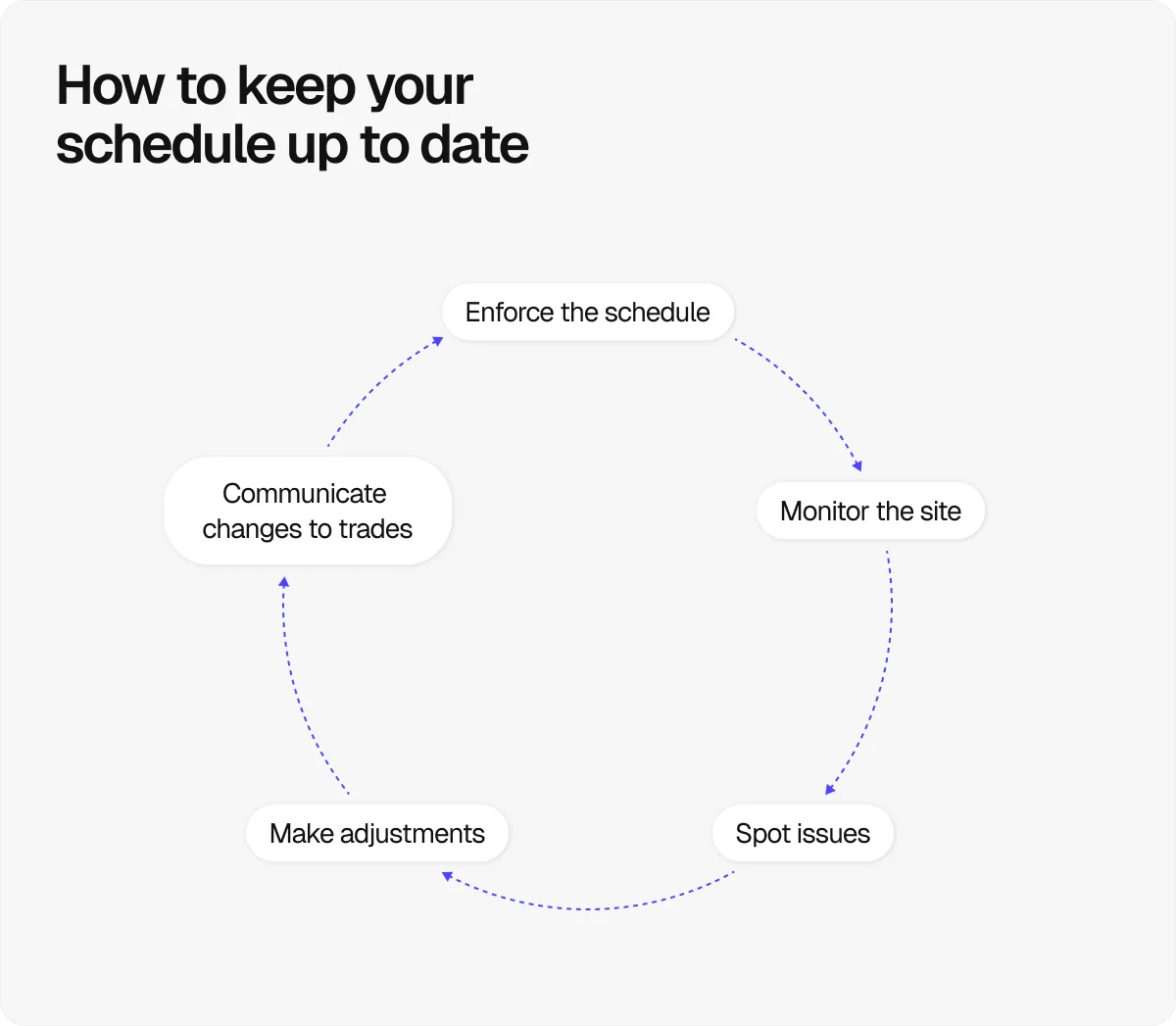

9. Review and adjust the schedule regularly

A construction schedule isn’t something you can create once and forget. If it isn’t reviewed and updated, it quickly stops reflecting what’s actually happening on site.

Missed milestones, small changes, and unexpected delays add up quickly. When the schedule stays static, problems stay hidden until they’re much harder to fix.

Regular reviews help you spot issues early and adjust before they affect other trades. Tracking progress, updating dates, and sharing changes keeps everyone aligned on what’s changed and what comes next.

Keeping the schedule up to date helps avoid construction scheduling issues such as:

Working with outdated dates

Hidden delays building up

Trades clashing on site

Late reactions to change

Loss of trust in the schedule

10. Use technology to support the schedule

If there’s one decision that strengthens every other part of construction scheduling, it’s using the right technology. Spreadsheets and whiteboards can only take you so far since modern projects move too fast for manual systems.

Construction scheduling software gives you a single source of truth. It allows you to track progress in real time, update schedules as conditions change, notify teams instantly, and keep records of decisions, deliveries, and daily activity.

It also helps manage resources, monitor subcontractor performance, and spot risks before they turn into delays.

Using technology helps you avoid:

Missed updates and miscommunication

Poor visibility across trades

Last-minute firefighting

Onetrace: Put the right tools behind your schedule

Deciding to use technology isn’t always enough if you don’t also choose the right tools.

Onetrace is purpose-built software for subcontractors designed around how work actually happens on site, helping teams stay organised, compliant, and on schedule without slowing them down.

Onetrace supports the key ways to avoid construction scheduling issues:

Clear planning: Onetrace’s visual planner shows exactly who is working on each site, on which days, and how teams are allocated across projects.

Realistic schedules: Live timesheets, GPS-backed attendance, and daily activity data give a reliable picture of how long work actually takes on site.

Early action: Onetrace brings materials, compliance documents, and site readiness into one place, so issues are visible before work begins.

Contingency planning: Real-time visibility across teams, sites, and documentation helps managers spot risks early and adjust plans before delays escalate.

Clear expectations: Signed RAMS, toolbox talks, and operative declarations create a clear record of responsibilities and agreed working methods.

Open communication: A single shared system connects site teams and office staff, reducing missed updates and conflicting information.

Live updates: Progress, attendance, and work status are updated instantly, so decisions are based on current information, not last week’s reports.

If you want to see how this works for your projects and teams, book time with the Onetrace team for a tailored walkthrough.

Marketing Team

@Onetrace

The Onetrace marketing team is passionate about sharing insights, ideas, and innovations that help construction businesses stay connected, compliant, and efficient. Combining industry expertise with a love for clear communication, we aim to deliver content that empowers professionals to work smarter and safer.