Construction safety compliance: Everything you need to know

By

Marketing Team

@Onetrace

Construction is one of the highest-risk industries for workers.

In Great Britain alone, an estimated 50,000 construction workers report sustaining a non-fatal injury each year. That’s around 2.5% of the workforce—a rate significantly higher than the average across all industries.

These alarming figures underline the unparalleled importance of construction safety compliance.

Safety compliance, a core part of construction compliance, is about putting the right systems, behaviours, and controls in place to reduce risk on site. Done well, it helps prevent injuries, supports teams on the ground, and gives businesses a clear line of sight on their responsibilities.

With this in mind, we’ll examine what construction safety compliance covers, who’s responsible for it, and how to manage it in a way that supports safe, efficient work on site.

Key takeaways

Construction safety compliance is built around managing known high-risk activities

Regulations like HSWA, CDM, and supporting HSE guidance exist to control predictable risks. Compliance is about applying these rules consistently to reduce real harm to workers and the public.Most serious incidents stem from poor planning and weak controls, not unexpected hazards

Falls from height, machinery incidents, and long-term health issues are repeatedly linked to avoidable failures such as inadequate risk assessment and poor supervision.Clear responsibility and competent people are essential to staying compliant

Safety breaks down when roles are unclear or when accountability is diluted. CDM places specific duties on clients, designers, contractors, and workers. Compliance depends on the right people owning those responsibilities throughout the project lifecycle.Good compliance relies on communication, training, and evidence, not just paperwork

Safety policies are only effective if workers understand them, training is kept up to date, incidents are reported, and records are accurate and accessible. Centralised, well-maintained documentation is critical for audits, investigations, and day-to-day decision-making.Technology makes compliance easier to manage and harder to get wrong

Manual processes and fragmented systems make it easy for gaps to go unnoticed. Platforms like Onetrace give contractors real-time visibility across sites, clearer oversight of people and projects, and reliable compliance records in one place, helping teams stay compliant without adding admin.

5 common construction safety risks and compliance requirements

Construction safety is heavily regulated in every country where building work takes place. The risks are well-known, and the law is clear that they must be identified, managed, and controlled to protect workers and the public.

In the United Kingdom, for example, construction safety compliance is built around a small number of core regulations:

Health and Safety at Work etc. Act 1974 (HSWA): This is the foundation of all health and safety law in the UK, setting the overarching duty to protect workers and the public across all construction activity.

Construction (Design and Management) Regulations 2015 (CDM): The main regulation specific to construction defines safety responsibilities across the project lifecycle, from design to delivery.

Health and Safety Executive (HSE) regulations and guidance: These additional regulations provide practical rules and enforcement around high-risk activities such as work at height, as well as working with plant, lifting equipment, and hazardous materials.

Together, these rules are designed to address the most common construction hazards and reduce the likelihood of serious harm on site.

Here are five key risks they are intended to control, and the compliance measures that address them.

1. Working at height

Falls from height remain the leading cause of fatal injuries in construction. This is why controlling work at height is a critical safety priority.

In the UK, this risk is addressed primarily through the Work at Height Regulations 2005, which apply to any work where there is a risk of a fall that could cause injury, regardless of the height at which the work is done.

This includes work on:

Scaffolding

Ladders

Roofs

Fragile surfaces

Openings

The regulations require duty holders to follow a clear hierarchy of control, prioritising safer ways of working before relying on personal protection.

The hierarchy in question goes as follows:

Avoid work at height: Design or plan work so tasks can be completed from the ground when possible.

Prevent falls: Use collective protection, such as guardrails, scaffolds, platforms, or mobile elevating work platforms (MEWPs), to prevent falls.

Minimise the impact of a fall: Where falls can’t be prevented, use measures like safety nets or fall-arrest systems to reduce injury.

2. Machinery and plant safety

Construction sites rely heavily on machinery and plant, from cranes and forklifts to hoists and lifting accessories.

When this equipment is poorly maintained, incorrectly used, or inadequately supervised, the consequences can be severe.

In the UK, machinery and lifting risks are primarily regulated under the Lifting Operations and Lifting Equipment Regulations 1998 (LOLER).

LOLER applies to any equipment used to lift or lower loads and places clear duties on those who own, operate, or control it.

From a compliance perspective, construction safety requirements focus on three core areas:

Safe equipment: Lifting equipment must be suitable for the task, clearly marked with safe working loads, properly installed, and maintained in a safe condition.

Planned and competent use: All lifting operations must be planned by a competent person, appropriately supervised, and carried out by trained and competent workers.

Inspection and examination: Equipment must be subject to regular inspection and thorough examination at legally defined intervals, with defects identified and addressed promptly.

3. Manual handling

In construction, manual handling refers to any task in which workers lift, lower, carry, push, or pull materials using physical effort.

When these tasks are poorly planned or repeated without proper controls, they can lead to musculoskeletal disorders affecting the back, shoulders, joints, and limbs.

In the UK construction sector, an estimated 41,000 workers suffer from work-related musculoskeletal disorders, accounting for over half of all reported ill health. The Manual Handling Operations Regulations 1992 (MHOR) set the legal requirements for manual handling at work, aiming to reduce the risk of injury.

This involves a set of duties:

Avoid hazardous manual handling: Eliminate manual lifting where possible, for example, by using mechanical aids or changing how materials are delivered.

Assess unavoidable tasks: Consider the risk based on the load, movement, environment, and posture involved.

Reduce risk as far as practicable: Modify loads, improve layouts, provide equipment, and ensure workers are trained to handle materials safely.

4. Hazardous substances

Construction work regularly involves hazardous substances, including dusts, fumes, chemicals, and harmful mixtures found in materials such as paints, cement, and fuels.

Without proper controls, exposure can lead to respiratory illness, skin conditions, and serious long-term disease.

In the UK, exposure to hazardous substances is regulated under the Control of Substances Hazardous to Health Regulations 2002 (COSHH), alongside related legislation for specific risks such as asbestos.

To stay compliant, COSHH requires contractors to:

Identify hazardous substances used or created by their work

Prevent exposure where possible, for example, by eliminating or substituting substances or processes

Control unavoidable exposure, using measures such as ventilation, safe systems of work, and appropriate personal protective equipment (PPE)

Provide information, training, and monitoring, so workers understand the risks and controls in place

5. Site access, traffic management, and public safety

Construction sites bring together workers, plant, delivery vehicles, and visitors, often in confined or shared spaces. This creates a high risk of people being struck by moving vehicles, falling into excavations, or being injured by materials or equipment leaving the site boundary.

Inadequate planning and control remain the root cause of these accidents. That’s why the HSWA and the CDM require contractors to organise sites so work can be carried out safely, without putting workers, visitors or members of the public at risk.

This means contractors must:

Plan and manage site traffic: Organise vehicle and pedestrian routes so they are suitable, clearly defined, and kept separate wherever possible.

Control site access: Define and secure site boundaries, prevent unauthorised entry, and manage who is allowed on site and where they can go.

Protect the public and vulnerable groups: Prevent materials, vehicles, and equipment from creating risks beyond the site boundary, with particular care around children and public-facing locations.

Communicate site rules clearly: Use signage, inductions, and instructions so everyone understands routes, hazards, and site controls.

How to maintain construction safety compliance: 7 key practices

Construction safety compliance is maintained through clear planning, responsibility, and ongoing control. Here are seven key practices to focus on.

1. Assign clear roles and responsibilities

Construction safety compliance depends on clear ownership.

When roles are poorly defined or filled by people without the right skills or authority, risks are missed, and accountability breaks down.

The table below summarises who is responsible for what under UK regulations:

Role | Description | Key safety responsibilities |

Client | The individual or organisation for whom the construction work is carried out | - Ensuring suitable arrangements are in place for managing health and safety throughout the project |

Principal designer | Designer appointed to lead health and safety in pre-construction | - Planning, managing, and coordinating health and safety risks before work starts - Sharing key information |

Principal contractor | Contractor in control of the construction phase | - Planning, managing, and monitoring site safety - Coordinating contractors - Ensuring standards are followed |

Contractors and subcontractors | Organisations or individuals carrying out construction work | - Managing risks created by their work - Complying with site rules and safe systems |

Workers | People carrying out specific construction tasks | - Taking reasonable care - Following instructions - Reporting hazards or unsafe conditions |

2. Manage risk early

Under CDM, duty holders are expected to identify foreseeable risks and put controls in place at the outset, particularly for higher-risk activities.

In practice, this means:

Identifying hazards early: Review designs, methods, and site conditions to spot foreseeable risks before work starts.

Assessing and recording risk: Carry out risk assessments that reflect how work will actually be done, recording findings where required.

Planning high-risk activities carefully: Put specific controls in place for higher-risk work, such as work at height, lifting operations, and exposure to hazardous substances.

Controlling the risk at source: Eliminate hazards where possible, or reduce risk through safer methods, equipment and sequencing, rather than relying solely on PPE or monitoring.

3. Set and communicate safety policies

Contractors must have effective health and safety arrangements in place, covering how work is planned, controlled, monitored, and reviewed.

This includes clear procedures for emergencies, such as evacuation and response to serious danger, with specific roles assigned to implement them.

But safety policies only work if they are understood.

Communicating them clearly, through inductions, briefings, and regular updates, helps ensure everyone on site knows what is expected and how to raise concerns.

Pro tip:

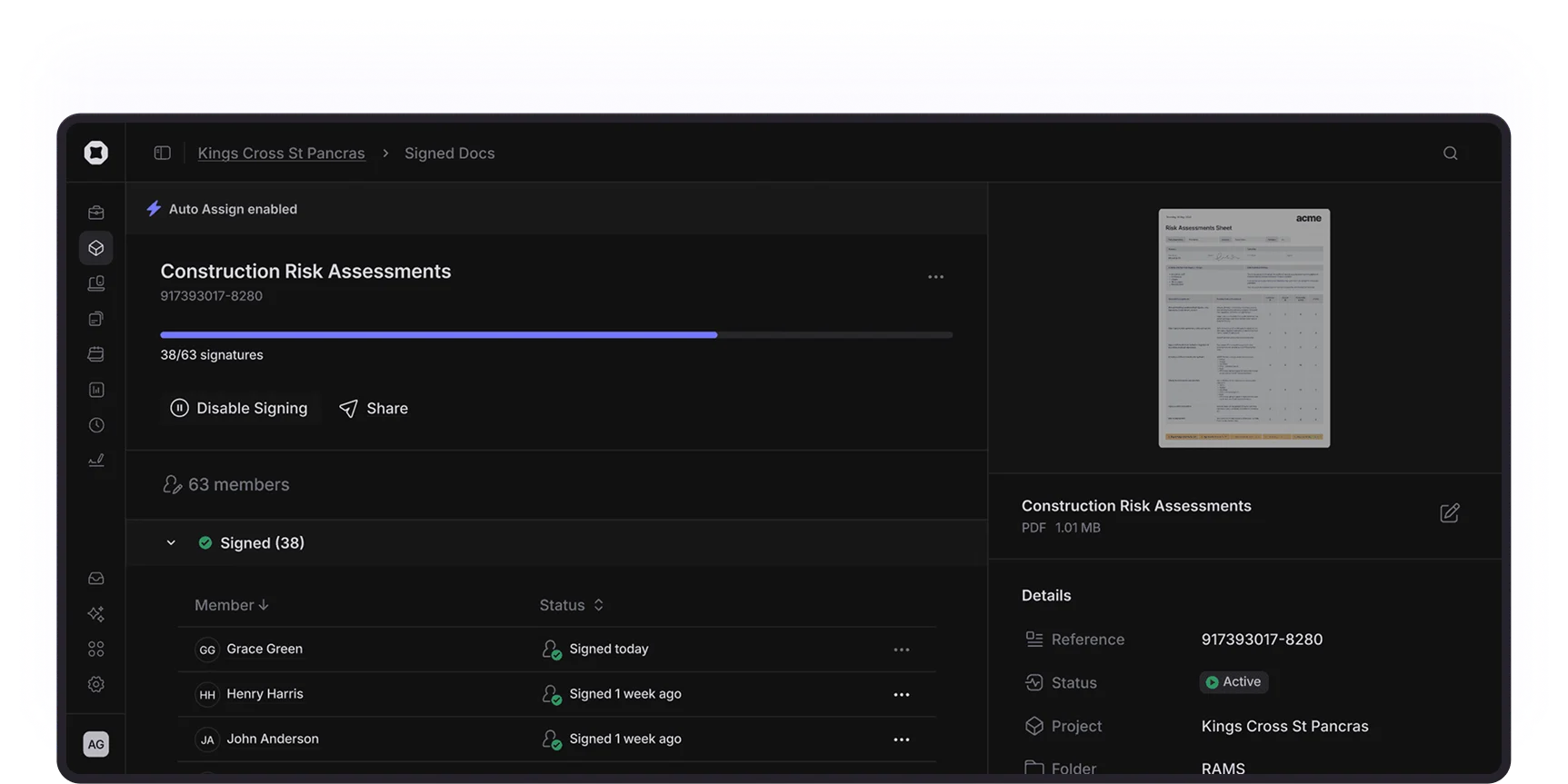

Add an extra layer of control by requiring workers to acknowledge key safety documents, such as RAMS, inductions, and toolbox talks. Signed confirmation helps demonstrate understanding, not just distribution.

Construction site management tools like Onetrace make this simple by allowing contractors to request, track, and store signatures digitally.

Workers can read and sign documents on their phone in a few clicks, while managers get real-time visibility of who has signed and who hasn’t, creating a clear audit trail.

4. Train and support workers

Construction safety compliance depends on workers’ understanding of the specific risks of their role and how those risks are controlled.

That’s why employers must consider workers’ capabilities when assigning tasks. They should also provide training at different stages of the project, including:

When workers first start on site (induction)

When tasks, roles or ways of working change

When new equipment, materials, or hazards are introduced

Training should cover safe systems of work, the correct use of equipment, and the right processes for when something goes wrong.

There should also be regular refreshers and clear supervision to help prevent mistakes, reinforce expectations, and ensure safety procedures are followed in practice, not just written down.

5. Keep records up to date

Accurate record-keeping is a core part of construction safety compliance. Clear, accessible records help demonstrate due diligence, track issues, and provide evidence during inspections, audits, or investigations.

Each trade will have its own required safety documentation, such as fire protection or electrical work, but safety compliance records generally include:

Risk assessments and method statements (RAMS)

Training, induction, and competence records

Equipment inspection and maintenance logs

Incident and near-miss reports

Permits and approvals for high-risk work

Keeping these records current supports better decision-making on site and gives contractors confidence that compliance can be shown, not just assumed.

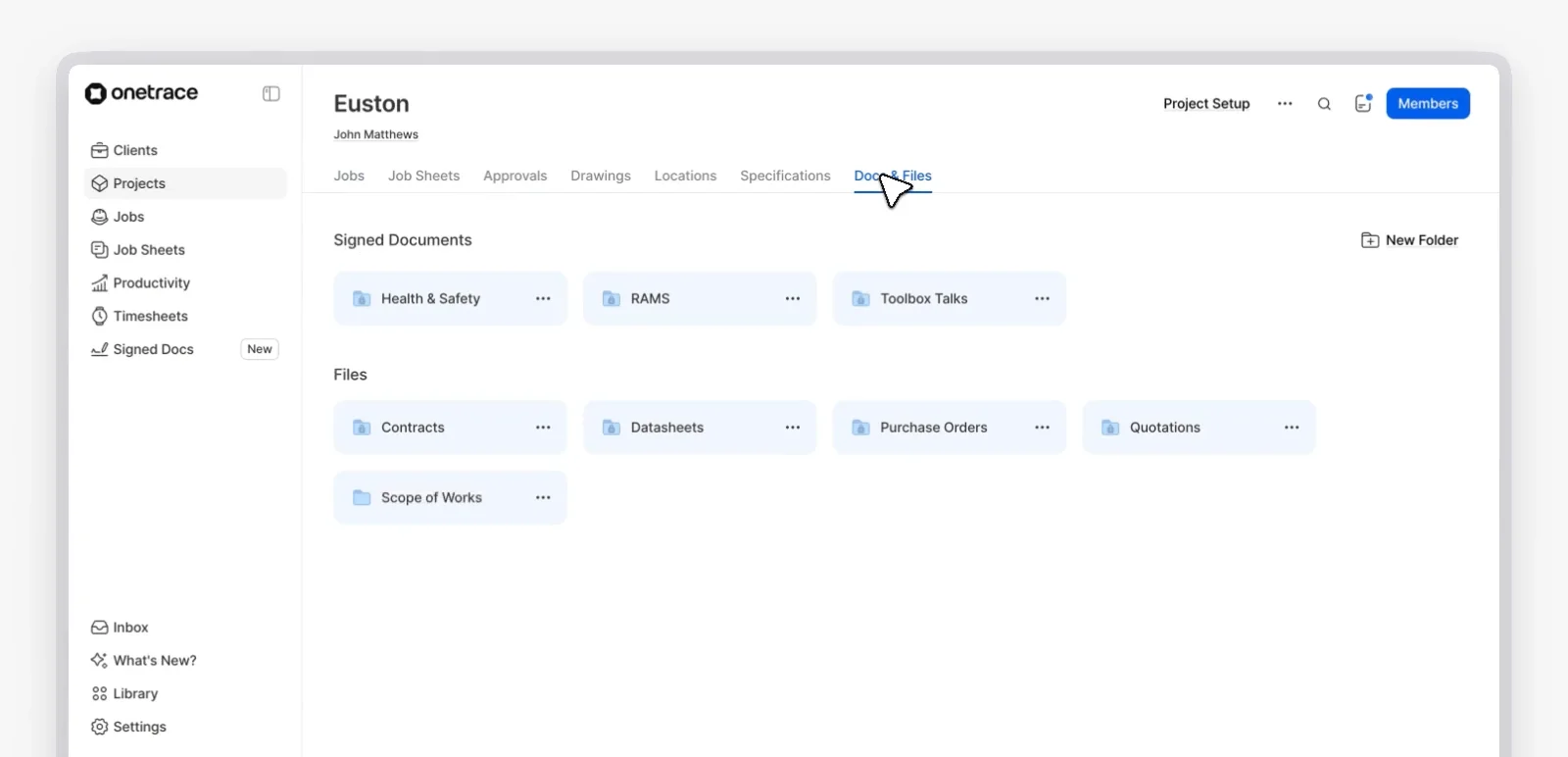

Pro tip:

Keep all safety records in one central place, rather than spread across spreadsheets, emails, and paper files.

Centralised records make it easier to manage documents across projects, spot gaps, and respond quickly to audits or incidents.

Onetrace supports this by providing a secure Docs & Files tab where all important documents can be stored together.

These documents stay clearly organised by project, making them easy to find, manage and share when needed.

6. Report and learn from incidents

The aim of construction safety compliance is to build a safety culture where issues are reported, understood, and acted on.

Reporting issues allows contractors to understand what went wrong, fix underlying causes, and prevent the same risks from reappearing. This includes learning from near misses, not just injuries.

7. Review and improve

Construction safety compliance isn’t a one-off exercise. Sites change, work progresses, and new risks emerge, so controls need to be reviewed and adjusted regularly.

As part of this process, contractors need to:

Carry out routine site inspections

Check equipment

Make sure processes remain safe

Update controls as conditions, methods, or teams change

Review records to spot recurring issues

Confirm actions have been completed

Regular reviews also help contractors stay prepared for inspections by regulators such as the HSE, where the ability to show active monitoring and continuous improvement is as important as having the right paperwork in place.

What happens if you don’t maintain construction safety compliance

When construction safety compliance falls short, businesses face legal, financial, and operational consequences. These include:

Enforcement action: Regulators can issue improvement or prohibition notices, require corrective action, or stop work if there’s a risk of serious harm.

Financial penalties: Prosecutions can result in substantial fines, calculated in part on company turnover, with higher penalties for serious breaches or repeat failures.

Operational disruption: Investigations, site shutdowns, and remedial work can delay projects, increase costs, and disrupt delivery schedules.

Insurance and liability risk: Non-compliance can lead to higher insurance premiums, reduced cover, or difficulties defending claims following an incident.

Increased regulatory scrutiny: Poor compliance often leads to more frequent inspections and tighter oversight from enforcement bodies.

Just as importantly, non-compliance can affect your reputation.

Enforcement notices and convictions are published publicly, which can undermine trust with clients, regulators, and insurers, making it harder to secure future work or win tenders.

Using technology to support construction safety compliance

Maintaining construction safety compliance across multiple sites is increasingly difficult without the right technology.

Manual processes and fragmented systems limit visibility, slow response times, and make it harder to spot issues before they escalate.

Digital platforms like Onetrace support construction teams by bringing key compliance activity into one connected platform, including:

Real-time site visibility, helping teams spot issues and gaps as work progresses

Clear project and operational oversight, keeping teams aligned with current plans and changes

Automated time and location data, supporting accurate records and accountability

By reducing reliance on manual reporting and disconnected tools, Onetrace helps contractors and subcontractors stay in control of compliance without adding unnecessary admin.

Book a personalised demo to see how Onetrace can support construction safety compliance across your sites.

Marketing Team

@Onetrace

The Onetrace marketing team is passionate about sharing insights, ideas, and innovations that help construction businesses stay connected, compliant, and efficient. Combining industry expertise with a love for clear communication, we aim to deliver content that empowers professionals to work smarter and safer.