What is construction scheduling? [+6 core methods]

By

Marketing Team

@Onetrace

On-site delays can come from all directions.

Missing information, late materials, or last-minute changes can all slow a job to a crawl.

But one issue sits above the rest, year after year: poor planning and unrealistic schedules.

So how do teams get ahead of this?

Most professionals point to the same set of fixes: tighter monitoring, better information flow, and stronger project management. Different ideas, but they all rely on one core practice: a clear, realistic construction schedule.

But what is construction scheduling, and why does it matter so much? This guide breaks it all down.

Key takeaways

A construction schedule is the backbone of a successful project

It defines every task, sequence, dependency, and milestone, giving teams a clear plan to follow. A well-built schedule improves decision-making, reduces confusion, and keeps the project moving in the right direction.Schedules fail when they’re unrealistic or not updated regularly

Poor planning is the top cause of delays. Without frequent updates, the schedule stops reflecting real site conditions, which leads to missed deadlines, resource clashes, and budget issues.The best schedules involve multiple stakeholders, not just one planner

Schedulers, project managers, supervisors, designers, engineers, subcontractors, suppliers, and clients all contribute essential information. When everyone aligns early, the schedule becomes far more accurate and achievable.Different projects require different scheduling methods

From CPM for tight deadlines, to PERT for uncertainty, to LOB for repetitive work, choosing the right method helps teams plan more accurately and avoid avoidable slowdowns.Technology is now essential to keeping schedules accurate and projects on track

Manual scheduling leaves teams fighting outdated information. Modern tools like Onetrace give you real-time updates, clear sequencing, streamlined workflows, and better coordination so you can deliver projects with fewer delays and far more confidence.

What is construction scheduling?

Construction scheduling is the process of planning how a project will be built: the tasks involved, the order they should follow, and the time each one needs. It sets out the path the team will take from first setting foot on site to handing the finished work over to the client.

In other words, construction scheduling isn’t about your regular shift patterns or day-to-day rostering.

It’s a structured way of mapping the whole job, including the links between different activities, the resources they need, and the milestones they lead to.

It’s also important to note that a construction schedule is a living document.

It must be reviewed and updated as conditions change, whether that’s weather, supply issues, or unexpected site findings, such as soft ground.

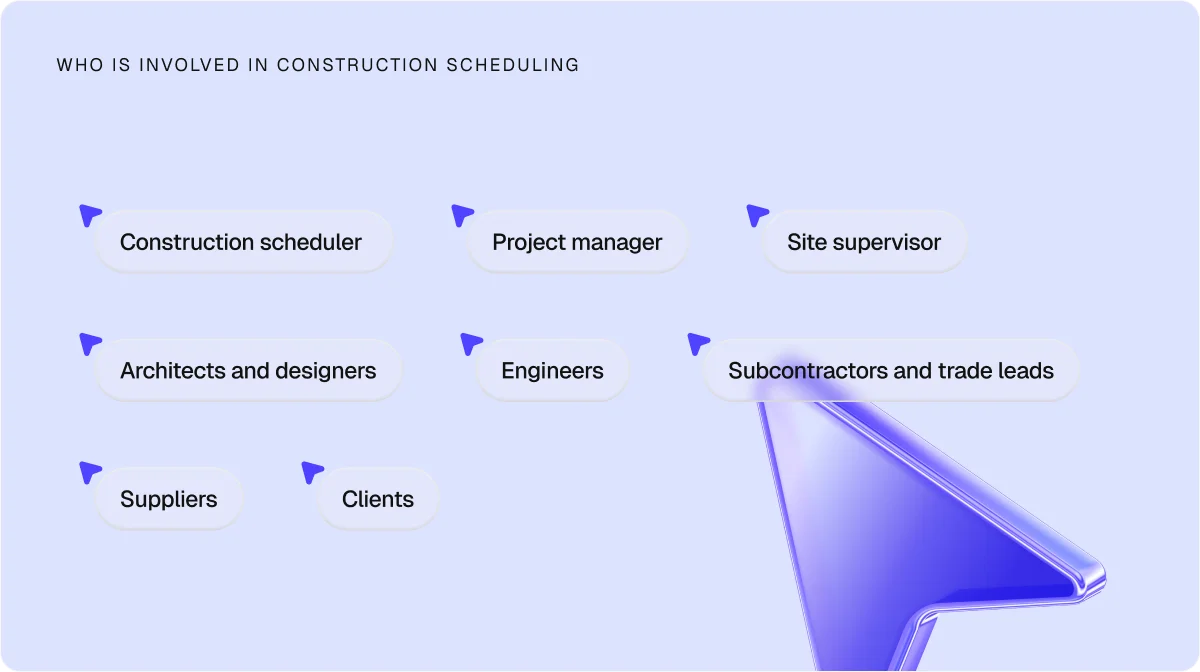

Who is involved in construction scheduling?

Construction scheduling isn’t a one-person job. It brings together a range of roles contributing their own expertise, including:

Construction scheduler: They build and maintain the schedule, ensuring tasks are sequenced correctly and durations are realistic.

Project manager: They oversee the entire scheduling process and align the programme with project goals.

Site supervisor: They bring practical, on-the-ground insight to make sure the schedule works in real site conditions.

Architects and designers: They ensure the sequence reflects the design intent and flag where design requirements affect timing.

Engineers. They provide technical input to anticipate structural, mechanical, or electrical constraints.

Subcontractors and trade leads: They supply accurate timings for their work and highlight dependencies between trades.

Suppliers: They confirm lead times for materials, equipment, and deliveries that affect sequencing.

Clients: They review and approve the schedule, making sure it meets objectives and expectations.

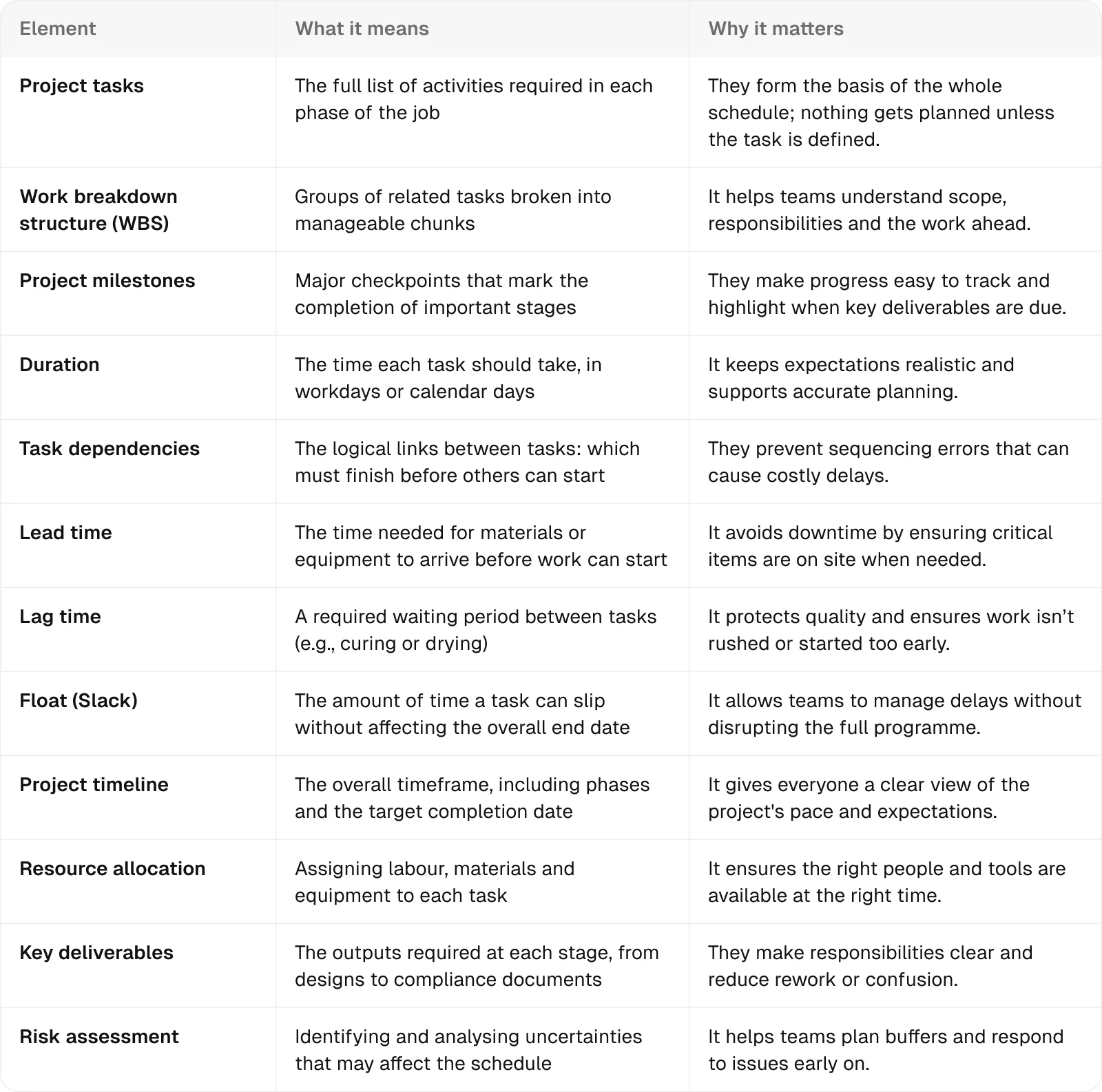

Construction scheduling: The key elements of a well-built schedule

By now, you should have a clear answer to the question “What is construction scheduling?” At least in simple terms. Now, let’s break down what this process actually covers in construction terms.

The table below outlines the core elements you’ll find in a well-built schedule and why they need to be there.

Given how many elements make up a construction schedule—and how tightly they all link together—trying to build and maintain one manually can only be a slow and error-prone process.

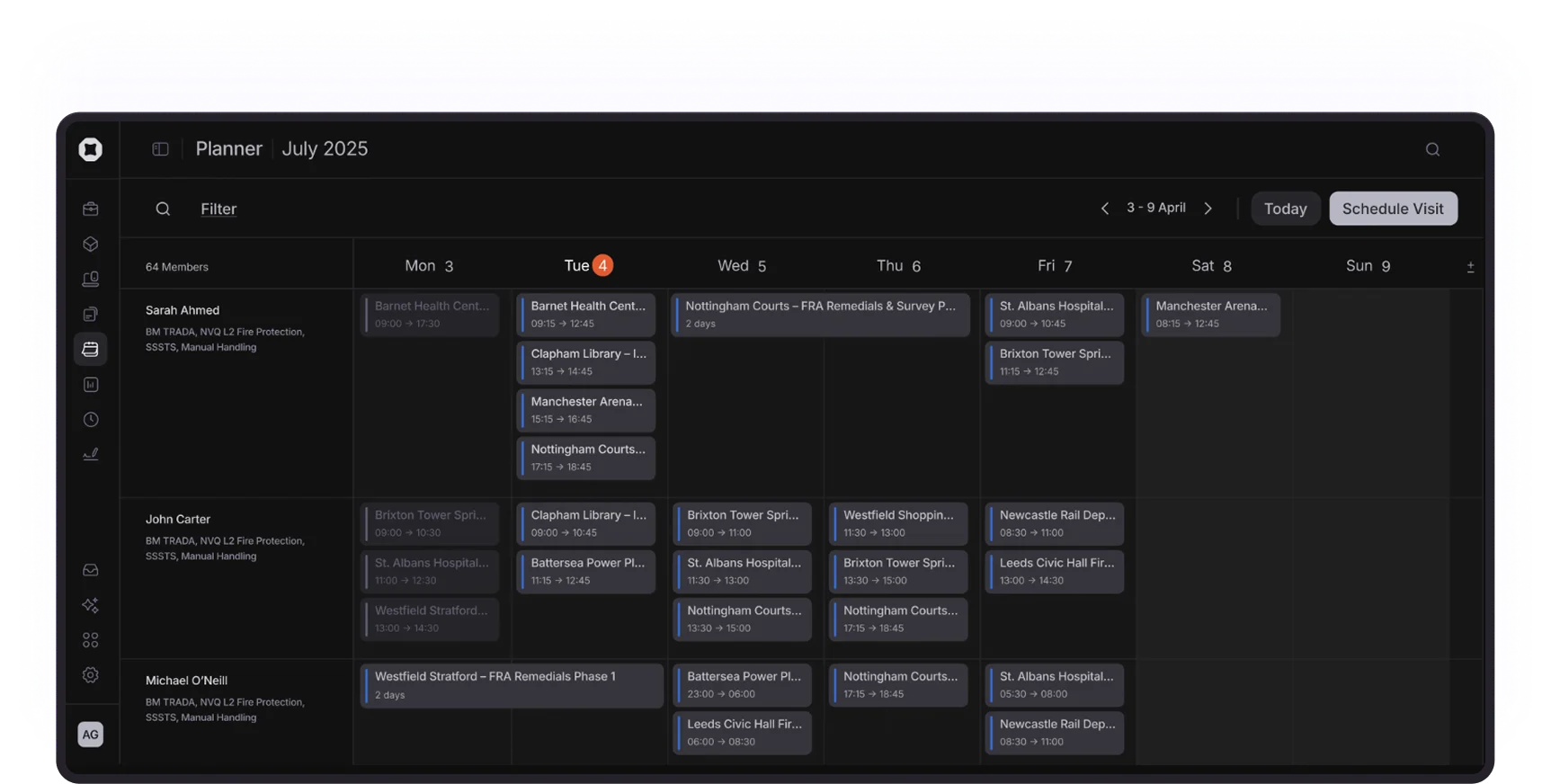

A far more efficient option is to use construction scheduling software like Onetrace.

Onetrace brings the core parts of scheduling into one place and helps you meet the requirements of a reliable, up-to-date schedule, with features like:

Planner: Schedule and reschedule operatives with a simple drag-and-drop, keeping everyone in sync.

Material tracking: Log material type, quantity, cost, and dimensions to support resource planning and reduce waste.

Deliverables and documentation: Use customisable forms with checklists, photos, text, and conditional fields to set out exactly what must be captured during a job.

Clear dependencies: Add site contacts and job-specific instructions so operatives know what must be completed before the next task can start, reinforcing proper sequencing.

Standardised inputs: Save form templates and use auto-fill options to keep data consistent across similar tasks or repeated work packages.

Construction scheduling: 6 core methods used across the industry

There’s no single construction scheduling method that works for every organisation. This overview of six well-established construction scheduling methods should help you choose an approach that fits your project, your team, and the way you like to plan.

1. Critical path method: The go-to approach for deadline-tight builds

The critical path method (CPM) maps every task required to complete the project, sequences them based on dependencies, and calculates the longest chain of activities (the critical path) that determines the shortest possible project duration.

Construction professionals use CPM because it:

Makes the overall timeline easy to visualise and understand

Highlights the tasks that truly drive the completion date

Helps direct labour and resources towards the most time-sensitive work

However, CPM isn’t without limits. The method can also:

Assume fixed task durations, which isn't always realistic on live sites

Overlook resource clashes when used on its own

Be less effective when dealing with large volumes of highly interdependent tasks

CPM suits teams working to tight deadlines, with clear sequences and little tolerance for slippage, such as commercial buildings, fit-outs, or any projects where milestone dates are non-negotiable.

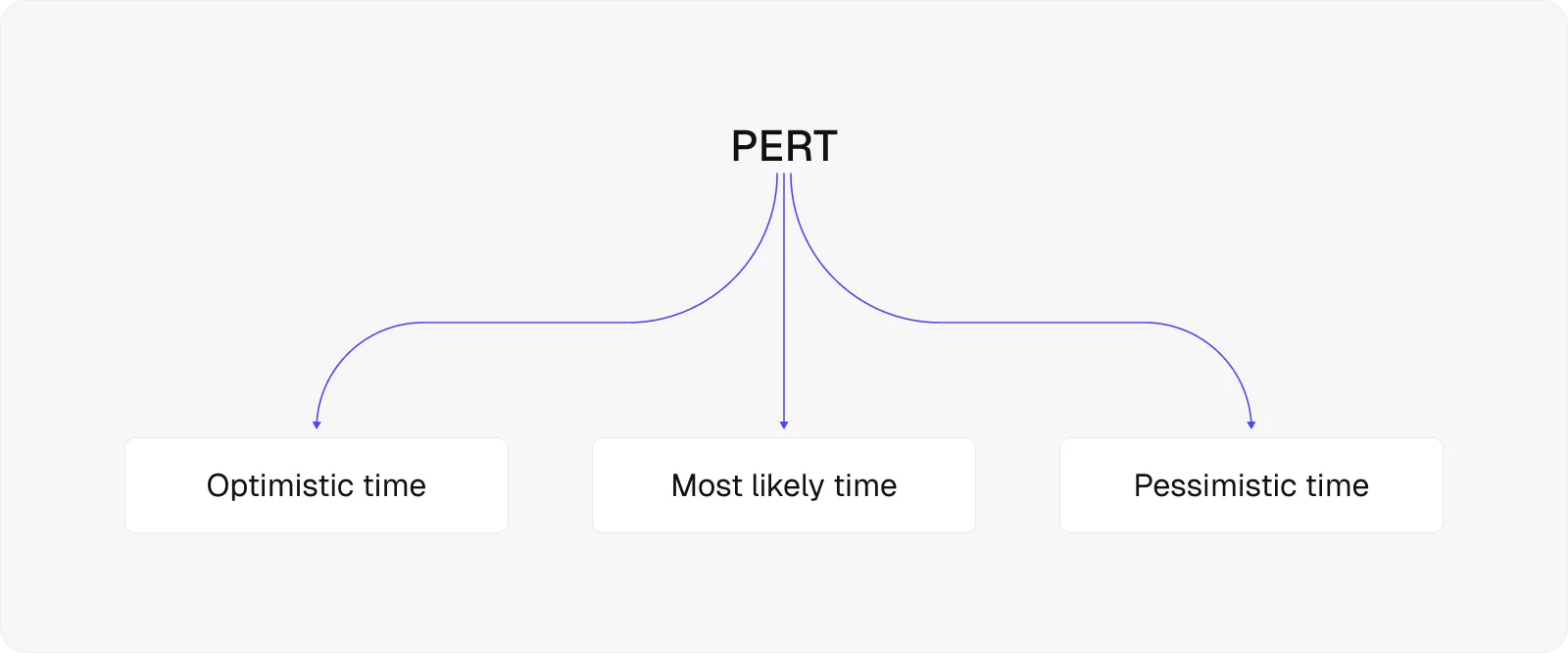

2. Program evaluation and review technique: The method built for uncertainty

Program evaluation and review technique (PERT) is a scheduling technique designed for projects where task durations aren’t easy to predict.

Instead of relying on a single estimate, it uses three time ranges—optimistic, most likely, and pessimistic—to calculate a weighted average for each activity.

This flexible approach is exactly where PERT’s strengths lie, as the method:

Handles uncertainty better than fixed-duration methods

Helps identify activities with the highest timing risk

Creates a clearer picture of best-case, worst-case, and expected outcomes

On the other hand, this approach also:

Requires three estimates per task, which can be time-consuming

Relies heavily on the accuracy of those estimates

Can become complex on very large projects

As a result, PERT suits teams working on complex builds where timing is hard to predict, such as transport hubs where systems integration must be tightly synchronised.

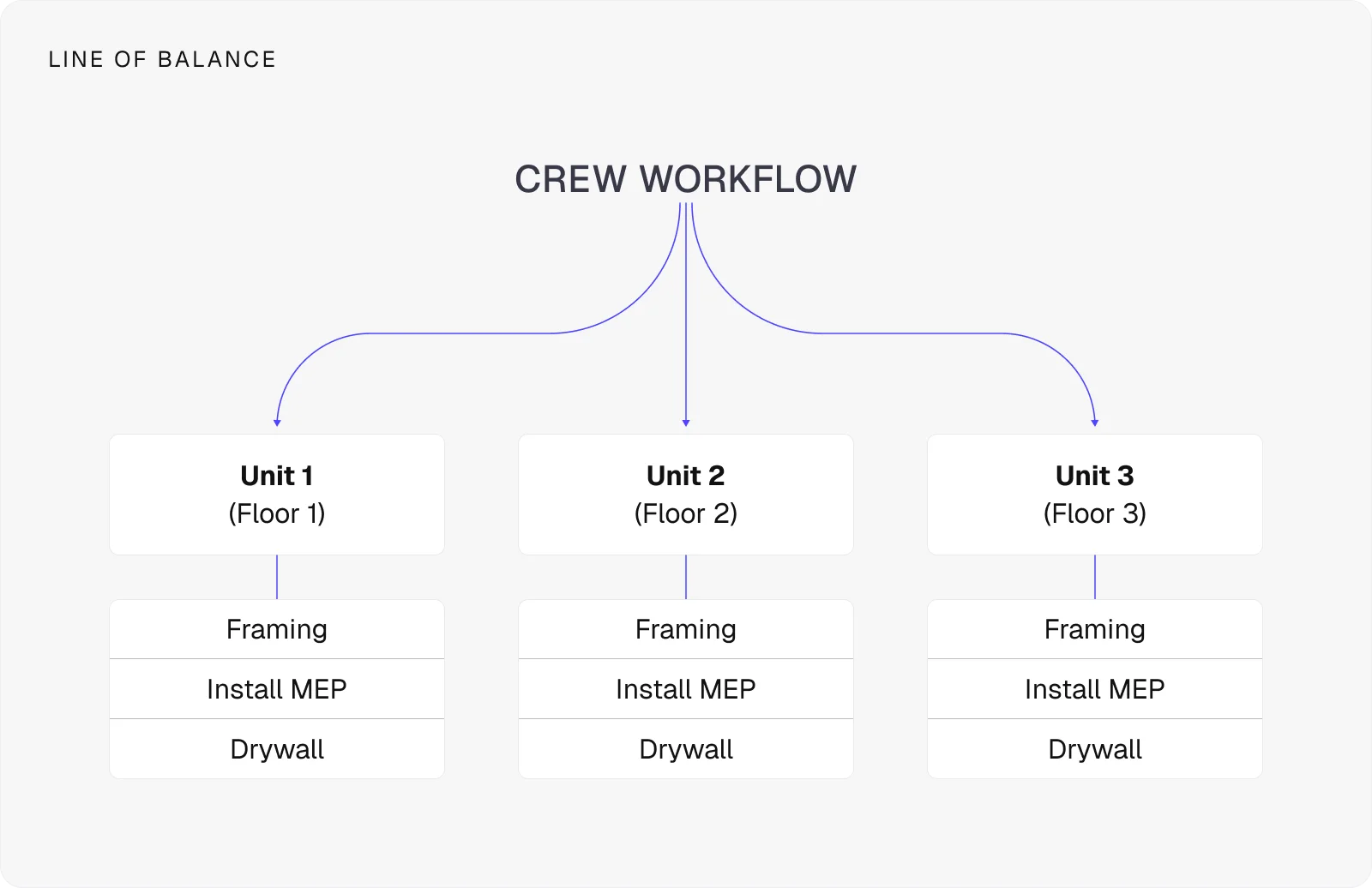

3. Line of balance: The method that keeps repetitive work flowing

Line of balance (LOB) is a scheduling technique designed for projects with repetitive tasks carried out across multiple units or locations, such as floors in a high-rise, plots in a housing development, or sections of a motorway.

Instead of focusing only on dates, it looks at production rates, and crew flow, showing how quickly each unit must be completed to maintain steady progress without gaps or downtime.

This approach allows LOB to:

Keep work moving in a continuous flow, thus optimising crew use

Make repetitive sequencing easy to visualise across floors, units, or sections

Help forecast performance and spot delays early

However, this focus on repetitive tasks makes LOB not suitable for tasks that significantly vary in duration between units.

4. Q scheduling: The method built around material flow and usage

Q scheduling (quantitative or queue scheduling) focuses on the materials, equipment, and quantities needed for each task.

It uses bar-chart visuals to show when and where resources are required, making it the only scheduling method that links task order directly to resource use and cost.

This clear overview makes Q scheduling ideal for projects where material quantities vary across units or work areas, such as:

Commercial buildings

Mixed-use schemes

Complex façades

At the same time, this approach makes Q scheduling less suitable for projects with heavy repetition. Plus, the method is still relatively new, meaning some teams may need training, and collaborators might struggle to understand it.

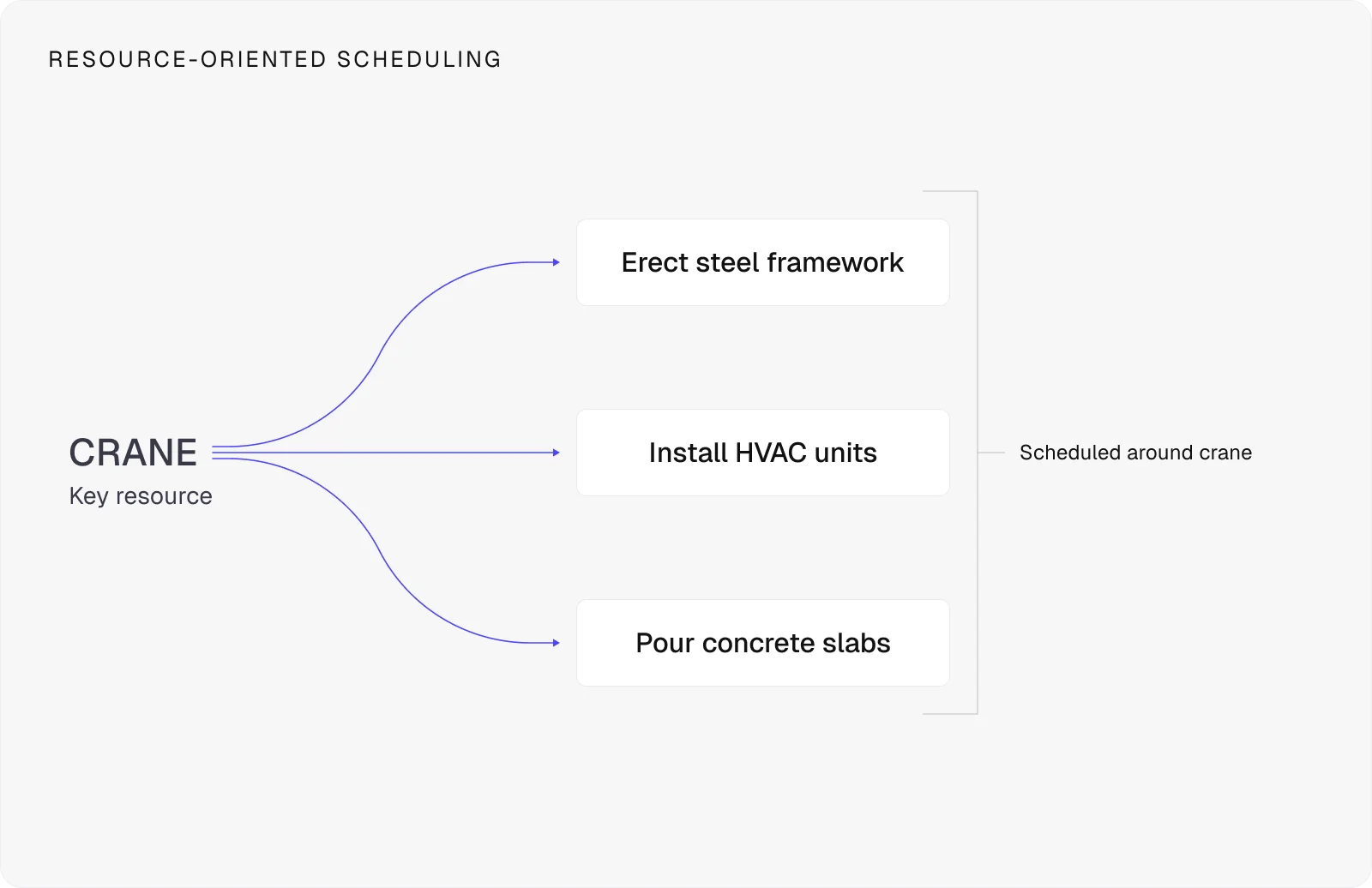

5. Resource-oriented scheduling: The method that plans work around limited resources

Resource-oriented scheduling starts by identifying limited or high-value resources, such as cranes, specialist equipment, and key trades, and builds the schedule around their availability.

Instead of pushing tasks based on sequence alone, it ensures that the right resource is free at the right time to avoid bottlenecks and downtime.

This allows it to:

Prevent clashes over shared or scarce equipment

Maximise the use of high-cost resources

Help reduce idle time and unnecessary costs

However, using this method can become complex when many resources need coordinating across multiple tasks.

That’s why it’s best-suited for projects where a few critical resources drive progress, such as high-rise builds with limited crane access or industrial facilities relying on specialist plants.

6. Last planner system: The method shaped by the people delivering the work

The last planner system (LPS) is a collaborative, commitment-based scheduling method rooted in lean construction.

Instead of pushing tasks down from the top, LPS brings the people who actually carry out the work (e.g., foremen and supervisors) into short-term planning sessions.

They agree on what can realistically be completed in the next one to six weeks, based on actual site conditions, resource availability, and known constraints.

This bottom-up approach:

Strengthens coordination between trades

Improves predictability by focusing on what crews can actually deliver

Reduces risk by identifying constraints early and planning around them

However, this approach also:

Requires strong collaboration and trust between teams

Relies on consistent participation from all key stakeholders

Can be time-consuming to establish and maintain

When you get it right, it works wonders on projects where many trades overlap and timing is tight, such as hospitals, large commercial buildings, and complex infrastructure schemes.

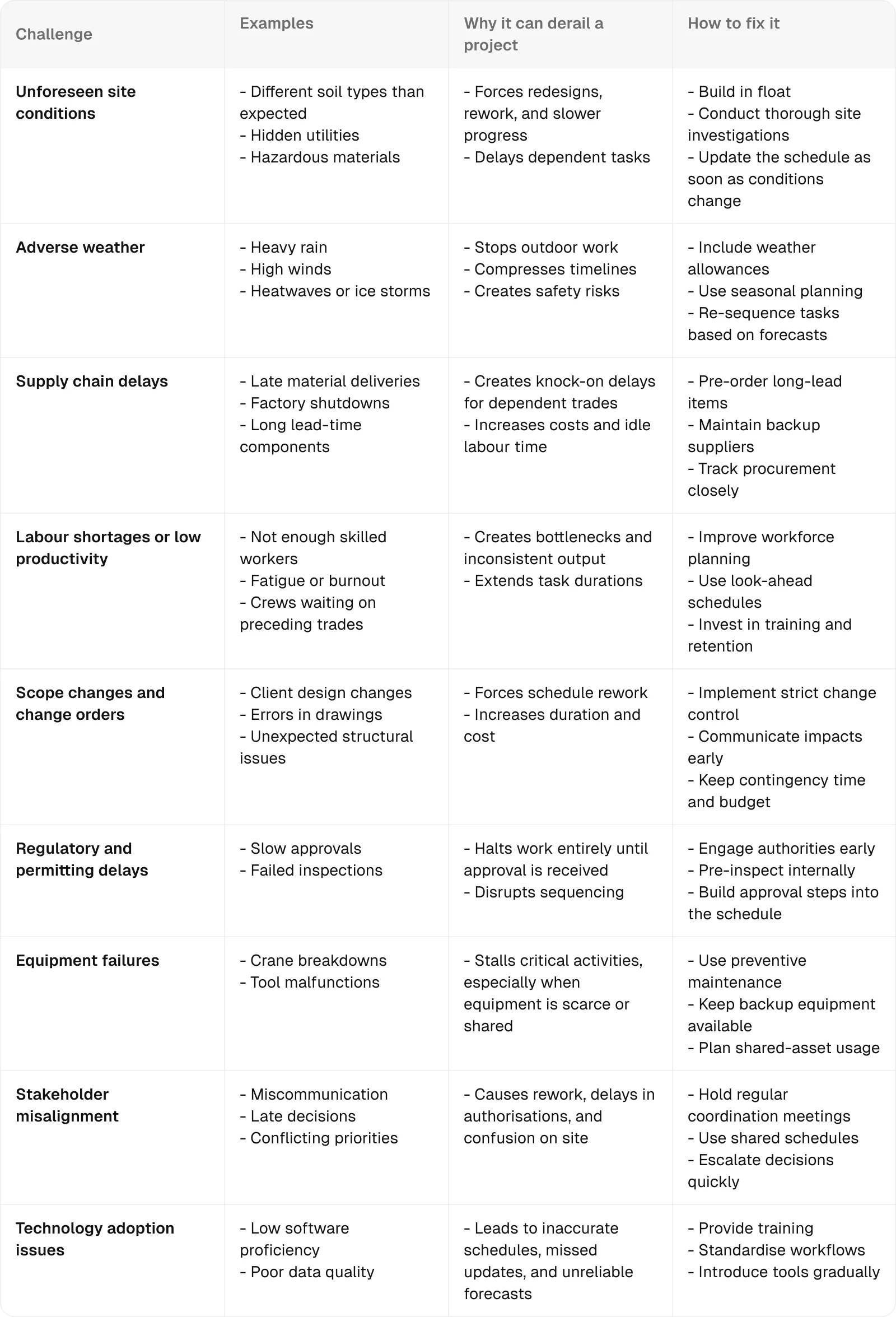

Common construction scheduling challenges and how to fix them

No construction project runs perfectly. That’s why it’s essential to anticipate the hurdles that can disrupt your schedule.

The table below outlines key scheduling challenges and how to keep them from derailing your project.

The good news? Many of the scheduling issues that slow projects down can be dramatically reduced with the right technology.

By adopting a user-friendly, easy-to-implement tool like Onetrace, you give your team the clarity, coordination, and control needed to stay on track.

With Onetrace, you can:

Stay aligned with real-time site visibility, ensuring progress updates flow instantly from the field to the office

Get a complete picture of your programme and labour usage, with schedules and timesheets displayed in one place

Spot scope changes as soon as they happen, thanks to live variation tracking built directly into the workflow

Embed your approval processes directly into the plan, so nothing moves forward without the right sign-off

Store and manage all compliance documents securely, keeping everything organised and audit-ready

Work smarter with reusable project templates, ensuring consistent, standardised delivery across every job

Maintain momentum with tailored workflow statuses, helping teams understand exactly what’s next

Why construction scheduling matters more than you think

Though construction scheduling might seem complex, it’s crucial you get it right. Why? Because when you do, you unlock benefits that keep the whole project running smoothly:

Better efficiency: Tasks are planned in advance, so crews stay productive and downtime drops.

Stronger communication: Everyone works from the same plan, which cuts confusion and keeps expectations clear.

Lower risk: Early planning helps you spot issues before they cause delays or drive up costs.

Tighter budget control: A realistic schedule reduces overruns by linking work, resources, and spending.

More reliable delivery: With a clear path to follow, projects are far more likely to finish on time.

Smoother coordination: Trades, suppliers, and subcontractors understand when their work fits in, reducing clashes.

Higher project quality: Work is given the right amount of time, reducing rework and rushed decisions.

Your construction schedule is only as strong as the tech behind it

What is construction scheduling without technology? A constant battle to keep information accurate.

Without digital tools, updates lag behind reality, communication breaks down, and even small issues snowball into delays, cost overruns, and rework.

That’s why tools like Onetrace matter. They keep schedules live, connected, and accurate.

Want to see what that looks like in action? Get a personalised walkthrough and discover how Onetrace makes scheduling simpler, clearer, and far more reliable.

Marketing Team

@Onetrace

The Onetrace marketing team is passionate about sharing insights, ideas, and innovations that help construction businesses stay connected, compliant, and efficient. Combining industry expertise with a love for clear communication, we aim to deliver content that empowers professionals to work smarter and safer.