8 challenges in construction project management [+Solutions]

By

Marketing Team

@Onetrace

Project management is what holds complex work together. It determines whether delivery moves forward in a controlled way or drifts off course.

While this is true across many sectors, construction, in particular, leaves very little margin for error.

In construction, work is organised around individual projects, each with its own conditions, teams, and constraints, often delivered under commercial pressure and changing conditions. Since there’s no steady operating rhythm to fall back on, control has to be built into the project itself.

This makes project management a defining capability in construction. Getting it right doesn’t guarantee success, but getting it wrong almost always leads to disruption.

Unfortunately, the realities of construction make it far easier to lose control than to maintain it.

To help you stay in charge, this guide outlines the main challenges in construction project management and shows you how to manage them effectively.

Key takeaways

Early decisions shape everything that follows

Weak project foundations are one of the fastest ways to lose control. When scope, roles, budgets, and timelines aren’t clearly defined at the start, projects drift into delivery with gaps in information.Delays are common and often outside your control

Schedule overruns affect a large share of construction projects, driven by weather, supply chain issues, approvals, and productivity challenges. You can’t prevent every delay, but you can limit the damage by planning realistically, tracking progress frequently, and keeping one shared, up-to-date programme.Cost overruns build quietly, not all at once

Going over budget is rarely caused by a single mistake. It usually stems from small, compounding issues such as weak estimates, rising input costs, rework, and late changes. Once overruns are obvious, it’s often too late to avoid them, which makes early visibility and discipline critical.Poor communication turns manageable problems into project risks

Construction involves many stakeholders, and when information is late, unclear, or fragmented, project management becomes reactive. Clear ownership, structured communication, and a single source of truth for drawings and instructions are essential to avoid rework, delays, and frustration.Technology only helps if teams actually use it

Many of the challenges in construction project management come down to visibility, coordination, and accountability. Onetrace brings these together in one easy-to-use platform, helping teams share schedules, track progress, manage quality, control costs, and keep everyone working from the same information.

1. Losing control early: Weak project foundations

Every successful build starts with solid foundations, and the same is true off site.

When the early groundwork on a project is weak, problems are almost guaranteed to surface later, when they are harder and more expensive to fix.

In construction, early planning should define:

What is being built

Who is responsible for what

How success will be measured

What the job is expected to cost

How long the project is expected to take

When the scope is loosely defined, roles aren’t clearly owned, and schedules are built on best-case assumptions, projects move into delivery with gaps in information. As a result, design clarifications arrive late, instructions change mid-job, and estimates are revisited as reality catches up.

How to solve it

Good foundations are built deliberately. To reduce the risk early on, you should:

Agree on a clear scope and success criteria before work starts

Break the project into defined work areas with clear owners

Check schedules and estimates against real constraints, not best cases

Set a simple, formal process for managing changes

Get key stakeholders aligned early, and confirm decisions in writing

2. Working under constant disruption: Schedule delays

In the UK, construction projects have historically overrun their planned schedules in around 42% of cases. In many instances, delays are measured in months rather than weeks, ranging from around 80 days under standard conditions to well over a year in exceptional circumstances, such as during the COVID-19 pandemic.

These delays can come from almost anywhere, often with little warning. In many cases, these issues sit largely outside the direct control of project teams, even when planning and coordination are sound.

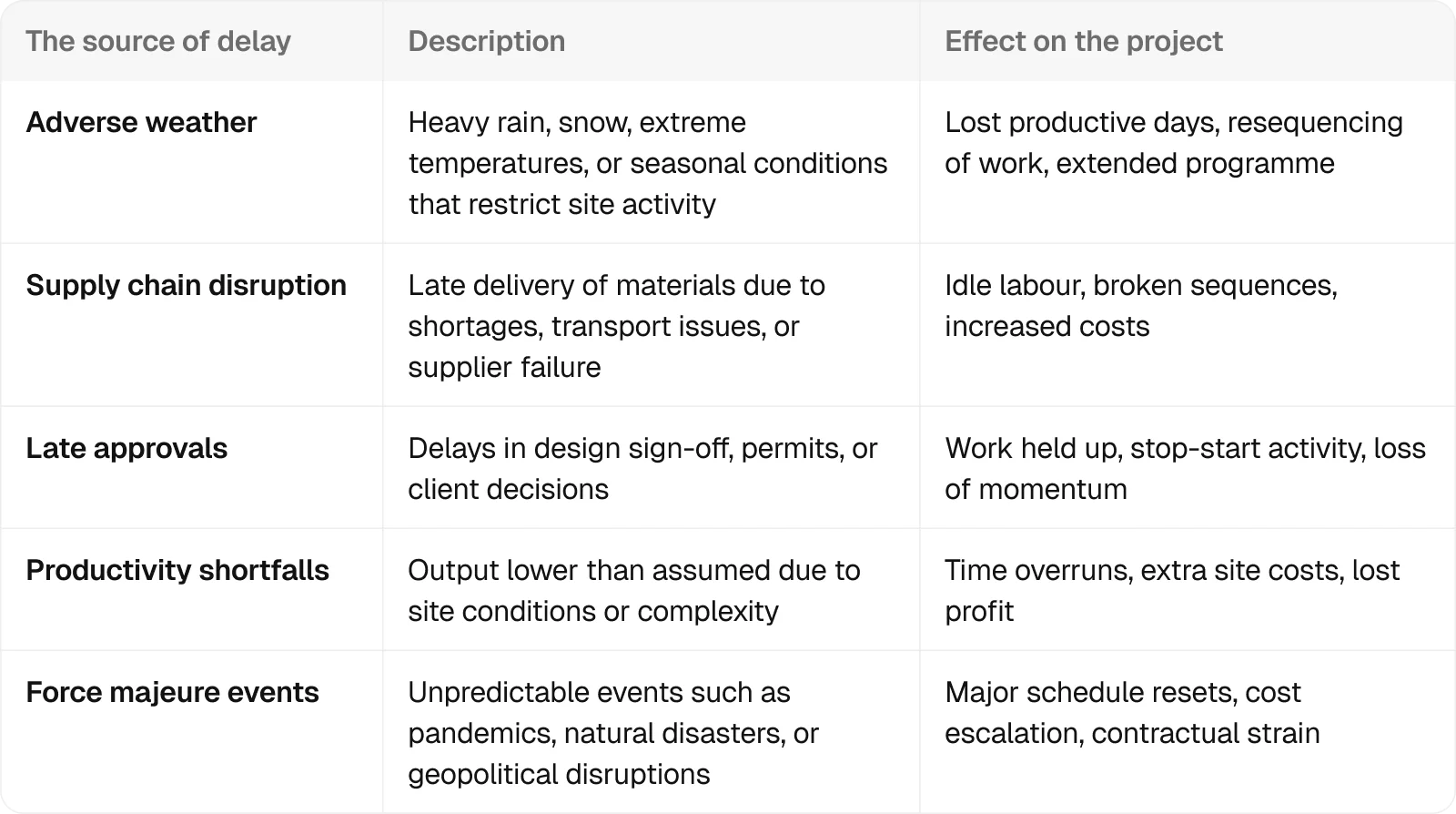

The table below outlines some of the most common sources of delay that construction teams are required to absorb during delivery.

How to solve it

You can’t prevent every delay, but you can reduce how much damage it causes by:

Building realistic float into the programme where risk is the highest

Using short look-ahead planning to spot clashes, missing information, or supply risks early

Tracing progress weekly against plan, not just milestones

Relying on scheduling tools to keep the programme current, visible, and easy to update when conditions change

Keeping one clear, up-to-date schedule that everyone is working from

Agreeing on how delays will be handled before they happen, including who decides on resequencing

3. Spending more than planned: Cost overruns

Going over budget is a common issue in construction. This happens in private projects just as much as it does in public ones, where around 70% exceed their original budgets.

However, spending more than planned is rarely due to one big mistake. It usually comes from a mix of poor early estimates, rising material and labour costs, rework, and late changes.

That’s what makes cost overruns hard to contain; by the time they show up clearly, the opportunity to avoid them has usually passed.

How to solve it

Keeping costs under control comes down to discipline. You should aim to:

Build realistic estimates based on current prices, not best cases

Track actual spend regularly, not just at key milestones

Control changes tightly, and confirm cost impact before approving them

Review cash flow often to spot pressure early

Address overruns quickly, before they become the new normal

4. Missing the full picture: Poor communication among stakeholders

Communication is such a persistent issue in construction that many studies describe construction problems as communication problems.

But this shouldn’t be surprising.

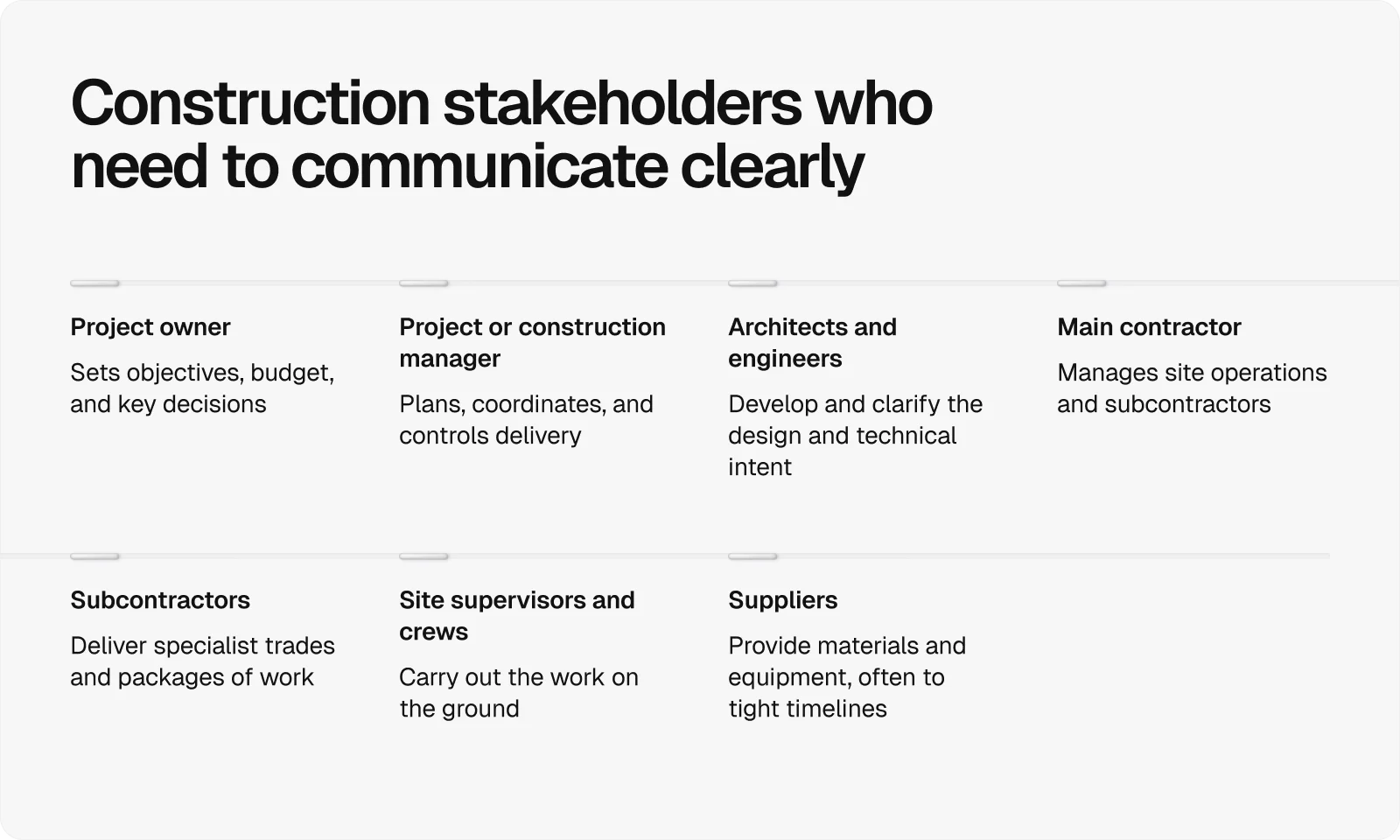

Construction projects bring together a large number of parties, each with different responsibilities, priorities, and pressures.

On a typical project, this includes:

Project owner

Project or construction manager

Architects and engineers

Main contractor

Site supervisors and crews

Suppliers

When communication between these groups breaks down, project management becomes reactive. Instructions arrive late or unclear, decisions are revisited, work is redone, and time and cost pressure increase.

How to solve it

Solving communication problems in construction depends on structure. You should:

Define who communicates what, to whom, and when

Make decision-making authority explicit

Use one central place for drawings, instructions, and updates

Hold regular coordination meetings with clear actions and owners

Confirm key instructions and changes in writing

5. Struggling to staff projects: Labour shortages

Labour shortages are one of the most pressing problems in construction today. In the UK alone, more than 140,000 construction roles remain unfilled, directly affecting productivity, programme certainty, and cost.

These figures make sense given that construction is still widely seen as one of the least desirable industries to work in. It’s physically demanding, high-risk, and often offers less predictable working conditions than other sectors competing for the same people.

For project management, this creates constant pressure.

Gaps in labour slow progress, reduce productivity, and increase reliance on overtime or short-term fixes. Plans that look possible in theory become difficult to deliver on site when the right people are simply not available.

How to solve it

Labour shortages can’t be fixed on a single project, but their impact can be reduced by:

Planning labour needs early and using realistic productivity rates

Securing key trades well ahead of when they’re needed

Building flexibility into programmes to cope with gaps

Using reliable subcontractors rather than last-minute replacements

Looking for ways to reduce site labour through prefabrication or off-site work

6. Managing hazardous sites: Safety risks

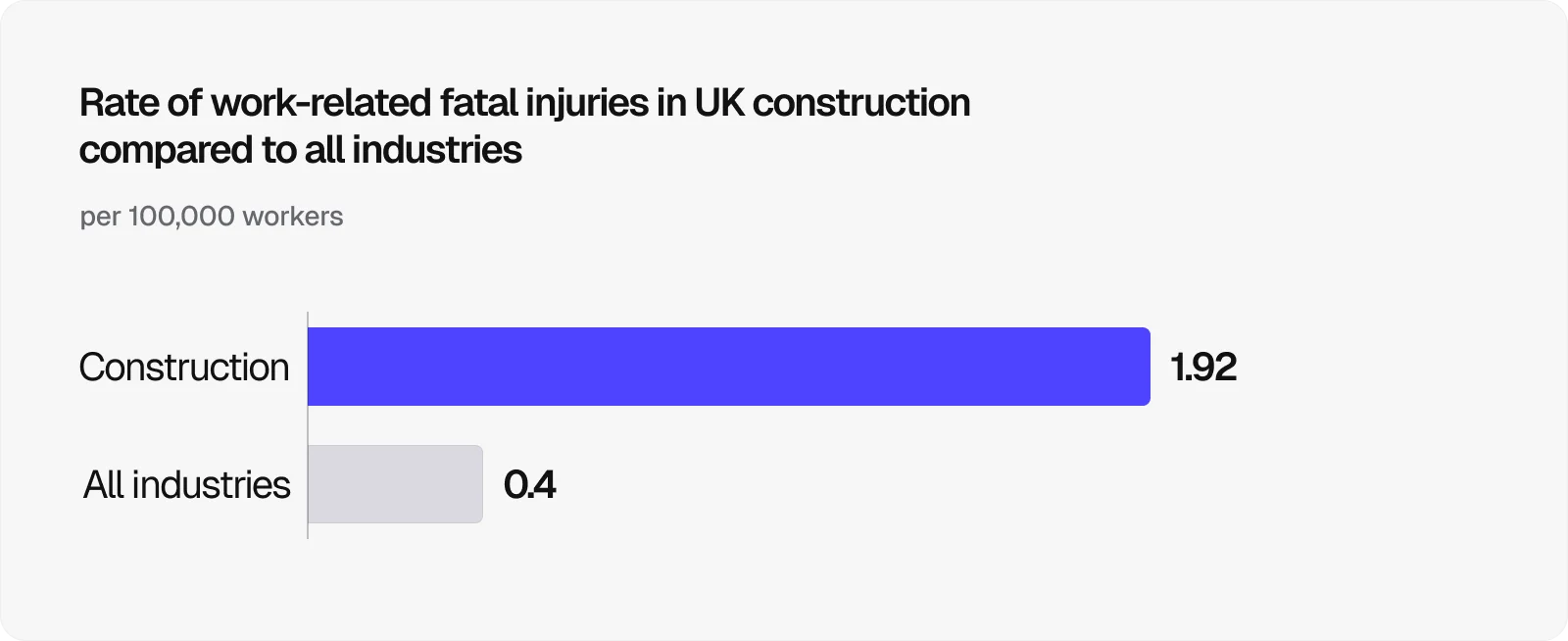

Construction carries higher safety risks than most other industries.

In the UK, construction has one of the highest fatal injury rates of any sector, and across Europe, it accounts for a disproportionate share of serious and fatal workplace accidents.

Beyond the human cost, accidents have a direct impact on project management. Injuries and near-misses disrupt crews, slow progress, and break momentum on site.

Additionally, investigations, stoppages, and compliance checks introduce delays, while morale and productivity suffer long after work resumes.

How to solve it

You can’t remove risk from construction, but you can reduce it by:

Applying clear, site-specific safety plans

Running regular Toolbox Talks focused on real site risks

Tracking near-misses, not just incidents

Giving workers clear authority to stop unsafe work

7. Keeping quality consistent: Quality control and rework

Mistakes in construction are far more expensive than many teams realise.

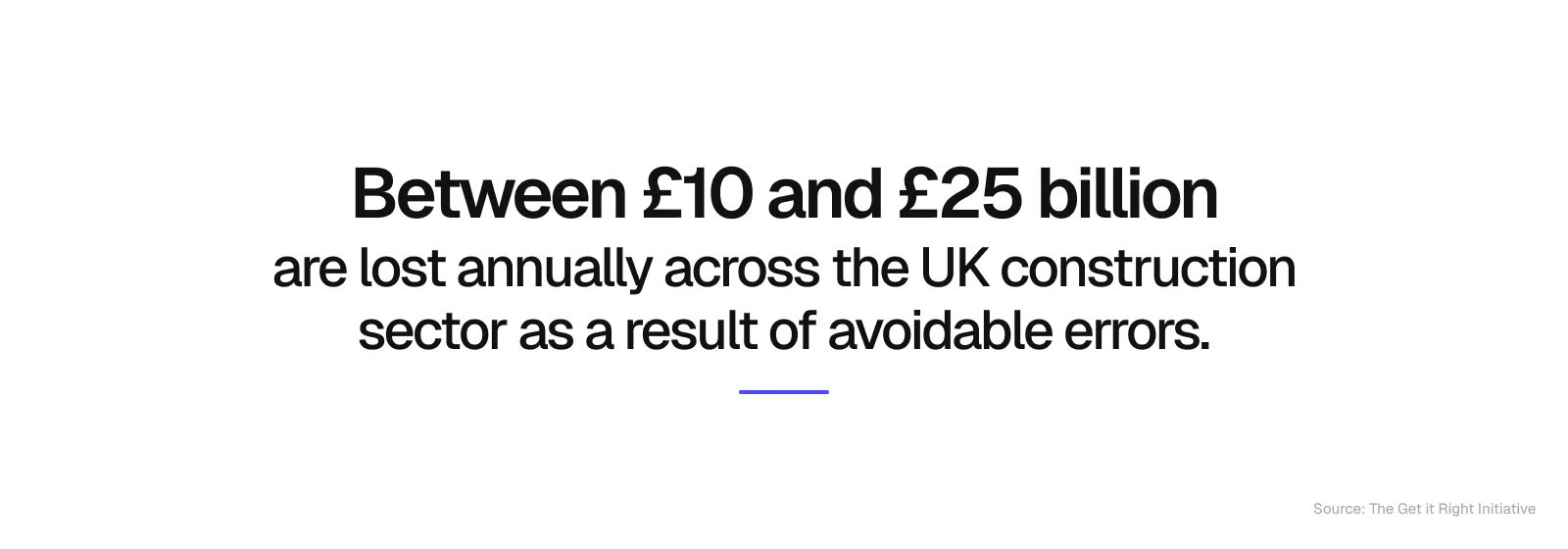

In the UK, avoidable errors account for around 5% of project value in direct costs, and when indirect and unmeasured impacts are included, the true cost of error is estimated at 10% to 25% of total project cost. Across the industry, that adds up to tens of billions of pounds each year.

For project managers, quality is difficult to control because problems often surface late.

Defects are hidden by progress, work moves on before checks are complete, and issues only become visible once follow-on trades are affected.

By then, fixing the problem means rework, disruption, and arguments over responsibility, not just a simple repair.

How to solve it

Consistent quality comes from early control, not late fixes. That’s why you should:

Set clear acceptance criteria before work starts

Use inspection and test plans for critical activities

Check work as it progresses, not at handover

Make supervisors responsible for quality on site

Act on defects immediately, before work moves on

8. Working with fragmented data: Technology adoption and use

Although digital tools can improve planning, reporting, and decision-making on construction projects, only around a quarter of professionals use them routinely.

This usually comes down to the perceived cost and effort of adoption, limited time for training, and a lack of clear demand from clients or senior stakeholders.

As a result, technology is often introduced slowly and unevenly, or it is used only by parts of the team, creating a real problem for project managers.

Without consistent technology use, data becomes outdated, visibility is reduced, and decisions are made without a full picture of what’s happening on site.

How to solve it

Technology only helps when it’s actually used. To encourage implementation, try:

Investing in construction management platforms that are easy to learn and use

Choosing tools that integrate scheduling, cost, and documents in one place

Training teams using real project scenarios, not generic demos

Standardising workflows so everyone works from the same information

Assigning clear ownership for keeping data up to date

How Onetrace supports better project management

Technology plays an increasingly important role in construction, even if adoption across the industry has been slow.

When done well, site management technology can reduce uncertainty, improve coordination, and give project managers better control over what’s really happening on the ground.

Onetrace can address all of the challenges in construction project management outlined in this article. Through its Traceability and Workforce Management products, it helps teams bring structure, visibility, and accountability to live projects.

You can use Onetrace to:

Establish one central place for drawings, instructions, and updates, avoiding version confusion

Build and share schedules everyone can access, anytime, from the site or the office

Visualise work ahead using the Planner, so teams can stay on track

Capture signed documents digitally, with a full audit trail for compliance

Run clear approval workflows, keeping quality checks and decisions moving

Track materials and control operative rates, giving early visibility of cost and productivity issues

Most importantly, Onetrace is easy to adopt and use.

Operatives can get started quickly, training time is minimal, and the platform works offline on site. As a result, teams are far more likely to actually use it, giving project managers reliable, up-to-date information to work with.

Book a personalised demo to see how Onetrace helps teams stay in control of live projects.

Marketing Team

@Onetrace

The Onetrace marketing team is passionate about sharing insights, ideas, and innovations that help construction businesses stay connected, compliant, and efficient. Combining industry expertise with a love for clear communication, we aim to deliver content that empowers professionals to work smarter and safer.