The complete fire door survey checklist to have in 2026

By

Marketing Team

@Onetrace

Fire doors are one of the most important passive fire safety measures in a building. When they fail, smoke and fire can spread more quickly, reducing the time people have to escape safely.

That’s why regular fire door surveys are essential. These checks confirm that each door is suitable for its location, installed correctly, and still able to perform as tested.

Fire door surveys are well established and largely standardised, but they only work when they’re carried out thoroughly and recorded properly.

To help you get this right, the fire door survey checklist below outlines the core checks you need to cover in a professional inspection, supporting a clear, consistent approach on site.

Key takeaways

Accurate identification underpins every inspection

Clear door details like location, floor, reference, and type make it possible to trace findings, link evidence, and ensure the right door is repaired or reviewed later.Fire doors must match their certified specification to perform

Certification labels, correct ratings, and consistency between the door, frame, and components are essential. If certification is missing or unclear, you can’t rely on the door to perform as intended in a fire.Small defects can seriously reduce fire performance

Damage to the door leaf, frame, gaps, seals, glazing, or ironmongery can all allow fire or smoke to pass early. Regular, methodical checks help catch these issues before they become serious risks.Closing behaviour and day-to-day use matter as much as components

Self-closers, hold-open devices, obstructions, and signage all affect whether a fire door is actually closed when it needs to be. A compliant door that’s wedged open offers little protection.Good surveys only work when findings and actions are controlled

Recording clear comments, assigning actions, and tracking follow-up is what turns inspections into real risk reduction. Tools like Onetrace help teams keep inspections, evidence, and approvals in one place, making it easier to manage fire doors properly across multiple sites and inspections.

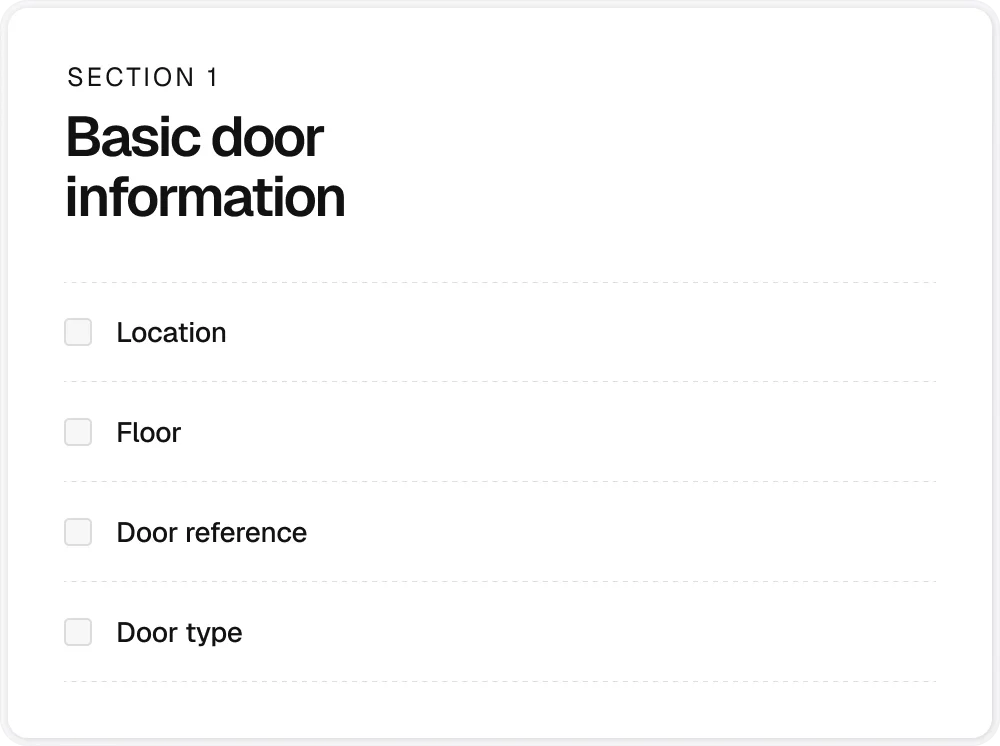

Section 1: Basic door information

This information clearly identifies the door being inspected. It makes findings easy to trace, avoids confusion later, and ensures any repairs or follow-up work are carried out on the correct door.

This section should include:

Location: Record where the door is within the building so it can be found quickly.

Floor: Confirm the level the door is installed on, which is especially important in larger or multi-storey buildings.

Door reference: Provide a unique identifier to link inspection records, photos, and remedial actions.

Door type: Confirm whether the door is a fire door, flat entrance door, or another fire-resisting door type.

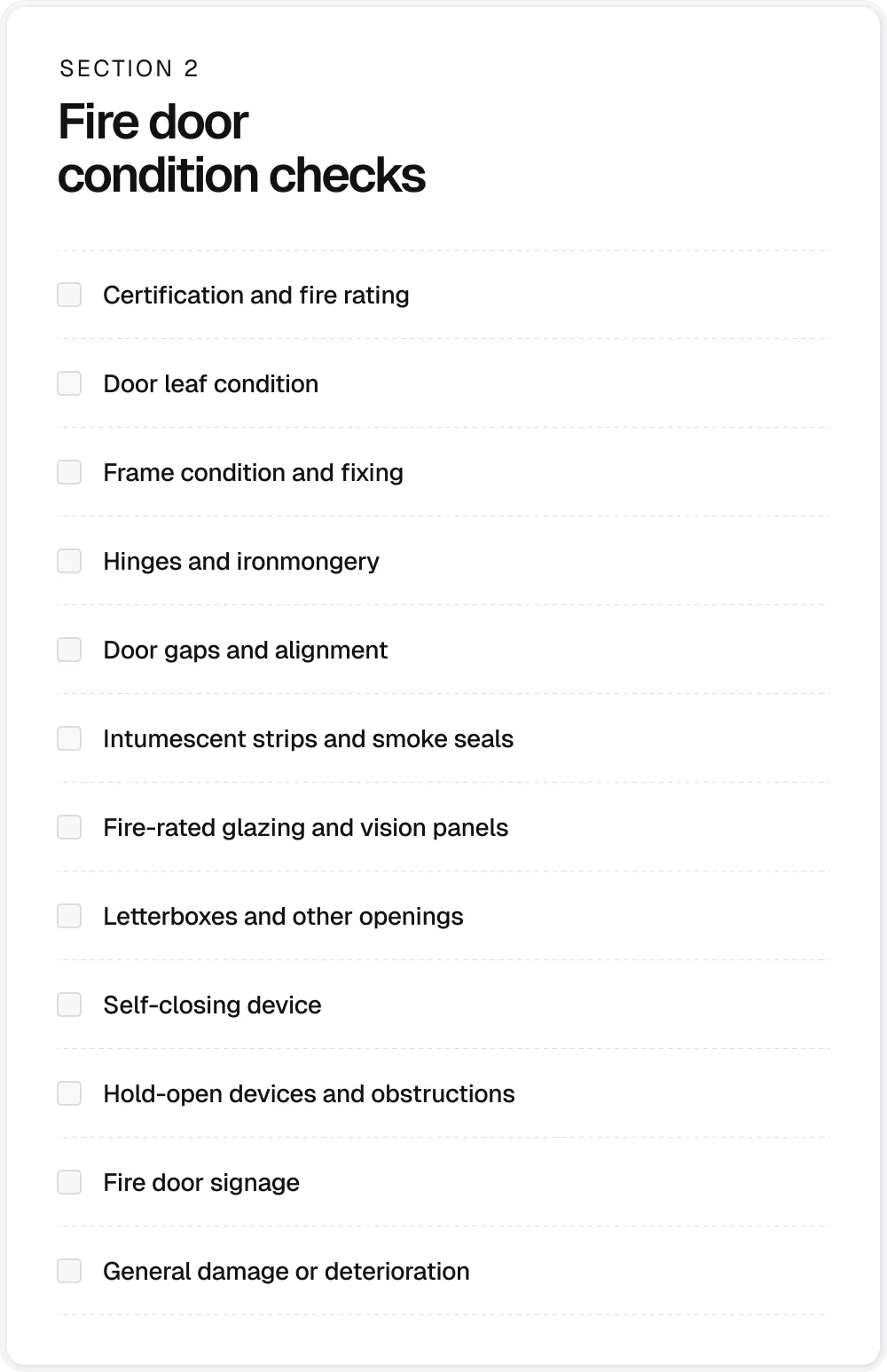

Section 2: Fire door condition checks

This section of the fire door survey checklist covers the core physical checks that confirm whether a fire door can still perform as intended.

Each of these 12 checks focuses on a specific component, helping you inspect doors consistently, identify issues early, and record findings clearly.

1. Certification and fire rating

Fire doors only provide protection if they match a tested and certified specification.

The certification label or plug confirms how long the door is designed to resist fire and whether it can be relied on as part of the building’s fire strategy.

If certification is missing, altered, or unclear, there’s no assurance the door will perform as required.

What to check

Does the door have a visible certification label or plug (for example, FD30 or FD60)?

Is the label or plug intact, legible, and free from paint or damage?

Is the label located in a typical position, such as the top edge of the door or near the hinge?

Does the stated fire rating match what’s required for this location?

Do the door leaf, frame, and key components appear consistent with the certified specification?

Has the door been replaced, altered, or repaired in a way that could affect its certification?

2. Door leaf condition

The door leaf forms the main fire-resisting barrier. If it is damaged, warped, or altered, fire and smoke can pass through more quickly than the door was designed to allow, reducing its effectiveness in an emergency.

What to check

Is the door leaf free from visible damage such as cracks, holes, or dents?

Is the door leaf flat and free from excessive bowing or warping?

Does the door sit flush within the frame, without protruding more than around 1 millimetre?

Are both faces of the door in good condition?

Have any unauthorised alterations been made, such as cut-outs, grilles, or removed hardware?

If modifications are present, do they match the manufacturer’s tested specification?

Does the door move freely without scraping or grinding?

3. Frame condition and fixing

The frame is critical to how a fire door performs. If it is damaged, loose, or distorted, the door may not close correctly or maintain the necessary seal during a fire.

What to check

Is the frame free from visible damage, dents, or missing sections?

Is the frame securely fixed to the surrounding wall with no signs of movement?

Is the frame square and free from distortion or twisting?

Are there any gaps between the frame and the wall that could affect performance?

Are the meeting stiles on double doors aligned correctly?

Have any components been removed or altered around the frame?

If damage is present, is it minor and repairable, or significant enough to require replacement?

4. Hinges and ironmongery

Hinges and ironmongery hold the fire door in place and allow it to close and latch properly.

If these components fail under heat, or are incorrectly specified or fitted, the door may drop, jam, or fail to stay closed during a fire.

What to check

Are there at least three hinges fitted to the door?

Are all hinges fire-rated and suitable for the door’s fire rating?

Do the hinges have a CE or UKCA mark and a fire identification stamp?

Are all screws present, secure, and of the correct type and size?

Are the hinges free from visible damage, excessive wear, or oil leaks?

Are locks, latches, and handles fire-rated and compatible with the door?

Does the latch engage fully into the strike without rattling?

Does the handle operate smoothly and return correctly after use?

Are intumescent pads fitted behind ironmongery where required?

Has any ironmongery been replaced, and if so, does it match the original specification?

5. Door gaps and alignment

Correct gaps allow a fire door to close properly while still sealing effectively in a fire. If gaps are too large, fire and smoke can pass through early. If they’re too tight or uneven, the door may stick, fail to close, or damage seals over time.

What to check

Are the gaps at the sides and top of the door between 2 and 4 millimetres?

Is the gap at the bottom of the door within the permitted size for the door type?

If smoke protection is required, is the threshold gap reduced accordingly?

Are the gaps consistent around the door when it is closed?

Does the door sit squarely within the frame without twisting or misalignment?

If a drop seal or threshold seal is fitted, does it make proper contact when the door is closed?

Have gaps been checked using an appropriate gauge or measuring tool?

6. Intumescent strips and smoke seals

In a fire, intumescent strips expand to block fire and hot gases, while smoke seals help limit the spread of cold smoke in the early stages.

If these components are damaged, missing, or poorly fitted, the door’s performance can be seriously reduced.

What to check

Are intumescent strips fitted where required for this door?

Are the strips continuous along the edges of the door or frame, without breaks or gaps?

Are the strips firmly fixed and free from damage, wear, or paint?

Are intumescent strips correctly fitted around ironmongery where required?

If smoke seals are present, do they make proper contact with the frame when the door is closed?

Are smoke seals free from damage and not loose, torn, or missing?

Have any seals been replaced, and if so, are they fitted as a continuous length?

If strips or seals aren’t present, is this consistent with the door’s age and original specification?

7. Fire-rated glazing and vision panels

Glazing and vision panels are part of the fire door’s tested construction.

If the glass, seals, or fixings fail, fire and smoke can pass through the opening early, reducing the door’s fire resistance and compromising escape routes.

What to check

Does the door contain glazing or vision panels?

Is the glass clearly identifiable as fire-resistant?

Is the glazing free from cracks, damage, or signs of impact?

Is the glass securely fixed, with no movement or rattling?

Are glazing beads firmly attached and free from damage?

Are intumescent glazing seals present, continuous, and in good condition?

Are seals correctly fitted between the glass and the bead?

If the glazing has been replaced, is it confirmed as fire-rated?

Where glazing is below 1,500 millimetres from the bottom of the door, is safety glass fitted?

Are vision panels clear and unobstructed on both sides of the door?

8. Letterboxes and other openings

Any opening in a fire door creates a potential weak point.

If letterboxes, vents, or other openings aren’t fire-rated or correctly fitted, they can allow fire and smoke to pass through far earlier than the door is designed to allow.

What to check

Does the door contain a letterbox, vent, grille, or any other opening?

Is each opening part of a fire-rated assembly suitable for this door?

Is the letterbox or opening securely fixed and in good condition?

Does the letterbox flap close fully without sticking?

Are intumescent liners fitted where required and free from damage?

Has the opening been installed in line with the door’s certification?

Are there any added openings that don’t appear to be approved or fire-rated?

9. Self-closing device

A fire door only works if it closes fully and stays closed. The self-closing device ensures the door returns to the closed position after use.

If the device is missing, damaged, or poorly adjusted, the door may be left open or fail to latch, offering little protection in a fire.

What to check

Is a self-closing device fitted where required?

Is the closer securely fixed and free from visible damage or leaks?

Does the door close fully into the frame from any position?

When opened slightly (around 75 millimetres), does the door still close and latch properly?

Does the door close within an appropriate time, without slamming?

Is the closer CE or UKCA marked and suitable for the door’s size and weight?

If a concealed closer is fitted, is the correct intumescent protection in place?

If a hold-open function is present, does the door release and close when the fire alarm is activated?

Is there any evidence that the door is being wedged or held open in use?

10. Hold-open devices and obstructions

Fire doors must be able to close when a fire occurs. Wedges, hooks, or unauthorised hold-open methods stop the door from doing its job.

Where hold-open devices are needed, they must release automatically when the fire alarm is triggered.

What to check

Is the door free from wedges, hooks, or other obstructions?

Is the door being tied, propped, or held open in normal use?

If a hold-open device is fitted, is it a compliant, alarm-linked device?

Does the hold-open device release immediately when the fire alarm is activated?

Is the hold-open device correctly positioned for the type of closer fitted?

Is the door able to close freely once the device releases?

Is there any sign that the hold-open device is straining the door or closer?

11. Fire door signage

Without clear signage, fire doors are more likely to be wedged open, locked incorrectly, or misused, reducing their effectiveness in a fire.

Signage also makes fire doors easy to identify during inspections and audits.

What to check

Is the correct fire door sign fitted to the door?

Does the wording match the door’s use (for example, ‘Fire Door Keep Shut’ or ‘Fire Door Keep Locked’)?

Is signage fitted on both sides of the door where required?

Is the sign clear, legible, and in good condition?

Is the sign the correct colour, shape, and style?

Is the sign positioned at a visible height, typically at eye level?

Has any signage been removed, damaged, or tampered with?

12. General damage or deterioration

Fire doors are exposed to daily wear and tear. Over time, environmental damage, poor repairs, or building movement can reduce performance even if individual components appear compliant.

This final check helps ensure nothing important has been missed.

What to check

Is there any visible damage not already covered in earlier checks?

Are there signs of water damage, swelling, delamination, or rot?

Is there paint build-up that could affect seals, hinges, or closing action?

Are there temporary or poor-quality repairs that could compromise performance?

Are there signs of impact damage from trolleys, equipment, or furniture?

Has general wear affected how the door fits or functions?

Does the door appear suitable for continued service, or does it need further assessment?

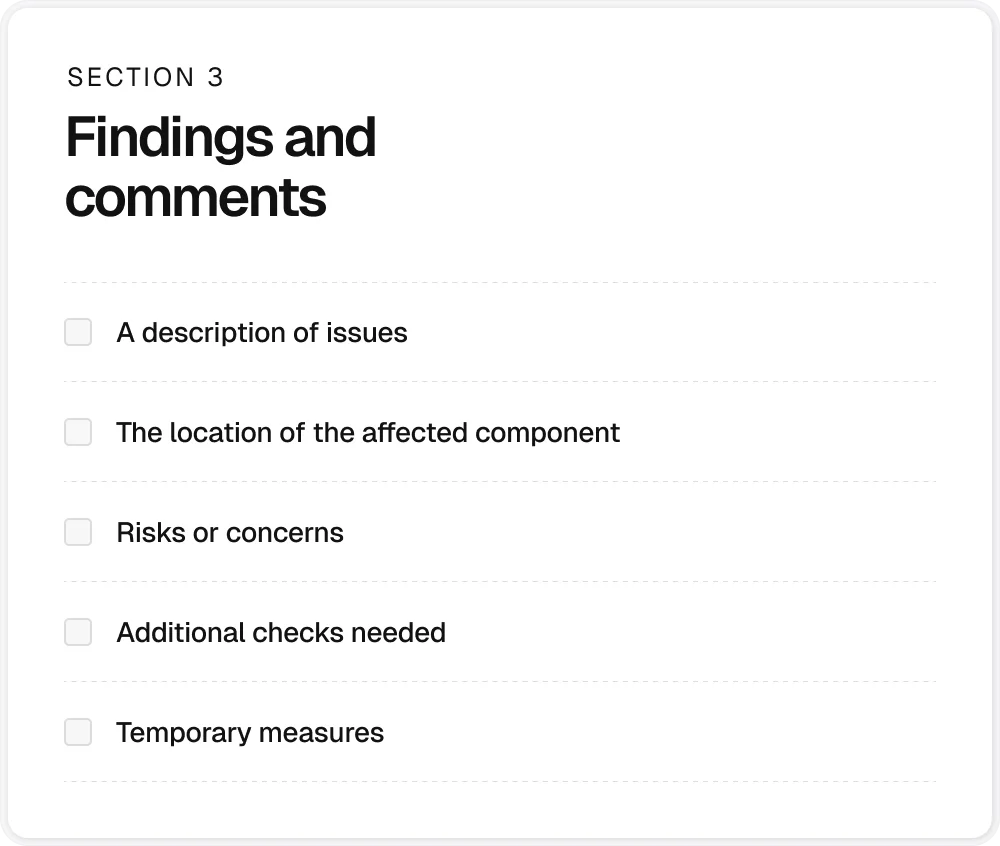

Section 3: Findings and comments

Use this section to record anything that needs explanation beyond a tick-box answer. Clear, concise notes help others understand what was found, why it matters, and what needs to happen next.

What to include

A brief description of any issues identified during the inspection

The location or reference of the affected door or component

Any immediate risks or concerns

Clarification on where a check couldn’t be completed or needs follow-up

Notes on temporary measures or observations that don’t fit elsewhere

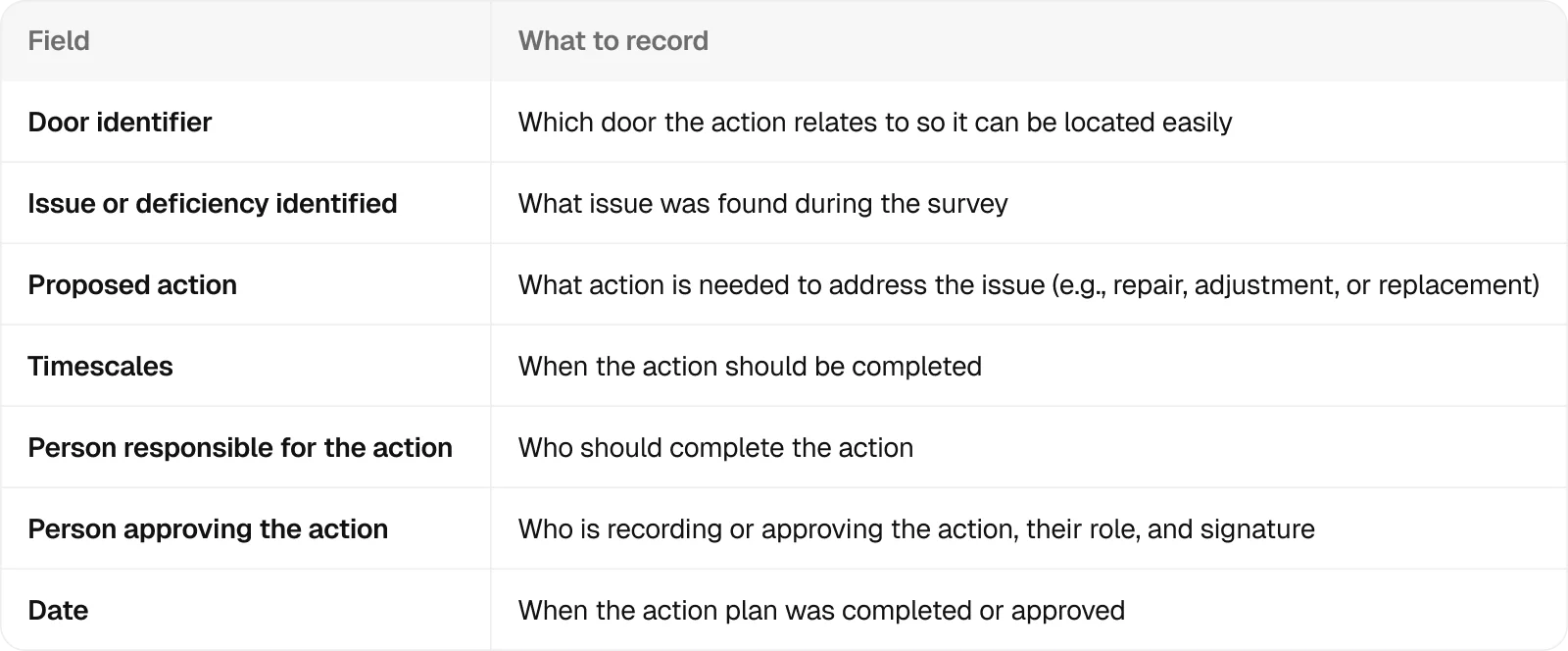

Section 4: Required actions

This section records what needs to be done to address issues identified during the fire door survey, by whom, and by when.

Clear actions help ensure findings are followed up on and resolved.

Onetrace: Supporting passive fire protection on site

A fire door checklist is only as good as the survey process itself. If checks aren’t recorded clearly, evidence is hard to trace, or actions aren’t followed through, even a thorough inspection can fall short.

That’s where the right fire protection software can help.

Onetrace is built around passive fire protection, including fire doors, and is designed to help teams stay in control as inspections scale across buildings, floors, and sites.

In practice, that means:

One place for fire protection documentation: Keep inspection notes, certificates, photos, and drawings together, so nothing gets lost or split across systems.

Clear door and location tracking: Organise buildings by blocks, floors, and zones, making it easier to link checks and actions back to the right door.

Consistent inspection data: Use structured digital forms to capture the same information every time, supporting repeatable surveys and cleaner audits.

Photo evidence that stands up to scrutiny: Record issues and completed work with time-stamped images that clearly show what was found and when.

Straightforward follow-up: Track actions, statuses, and sign-offs so issues don’t drift between inspections.

On-site updates: Record checks as you go, keeping progress visible without extra admin at the end of the day.

When the app is used correctly, software doesn’t replace judgement or experience. It helps teams apply the fire door survey checklist consistently, keep a clear audit trail, and confirm that fire doors are being properly managed over time.

Book a tailored walkthrough with Onetrace and explore how it helps you keep inspections, evidence, and actions under control.

Marketing Team

@Onetrace

The Onetrace marketing team is passionate about sharing insights, ideas, and innovations that help construction businesses stay connected, compliant, and efficient. Combining industry expertise with a love for clear communication, we aim to deliver content that empowers professionals to work smarter and safer.