The complete guide to fire doors installation [7 steps]

By

Marketing Team

@Onetrace

Fire doors are one of the simplest yet strongest lines of defence in a fire. They hold back flames and smoke, slow the spread, and buy precious time for people to get out and for emergency crews to step in.

Yet, the Fire Door Inspection Scheme, the U.K.’s leading body for fire door surveys, found that out of more than 100,000 doors checked, three-quarters failed to meet the required standard.

And for 30% of those fire doors, the failure came down to one thing: poor installation. Too-wide gaps, the wrong foam, hardware that didn’t match—seemingly small errors with huge consequences.

So, this guide goes back to the basics.

It lays out what a sound fire doors installation involves and why each step matters.

Key takeaways

Correct installation matters more than people realise

Most fire door failures come down to installation errors like incorrect gaps or incompatible hardware. A compliant installation follows the manufacturer’s tested method exactly, not a general joinery approach.Preparation before installation is half the job

From choosing the right FD rating to checking humidity, storage, opening tolerances and tools, the groundwork determines whether the door will perform as tested once fitted.Every component must be certified and compatible

Hinges, closers, seals, frames, and even the fixings must match the door’s certification. One non-certified part can void the entire fire rating.Testing and documentation are non-negotiable

After installation, the door must be tested, tagged, and certified, then checked regularly through a proper maintenance routine to stay compliant.Digital tools make compliance far easier

Fire doors come with strict requirements, tight tolerances, and heavy documentation. Using a platform like Onetrace helps standardise installs, track materials, store certificates, and manage inspections so every fire door stays compliant from day one.

Start strong: 7 things to get right before a fire doors installation

A fire doors installation isn’t your typical joinery job. There are a number of points that need to line up first so the installation can start on solid ground.

Here are the seven questions you should answer before picking up your drill.

1. Who should carry out a fire doors installation?

A fire doors installation should only be carried out by someone who’s trained, competent, and knowledgeable about how the door is meant to perform. Ideally, the installer will be a part of a recognised quality assurance scheme, such as BM TRADA Q-Mark or FIRAS, so you know the work follows proven best practices.

2. What fire door and frame are right for this job?

There isn’t one “standard” fire door.

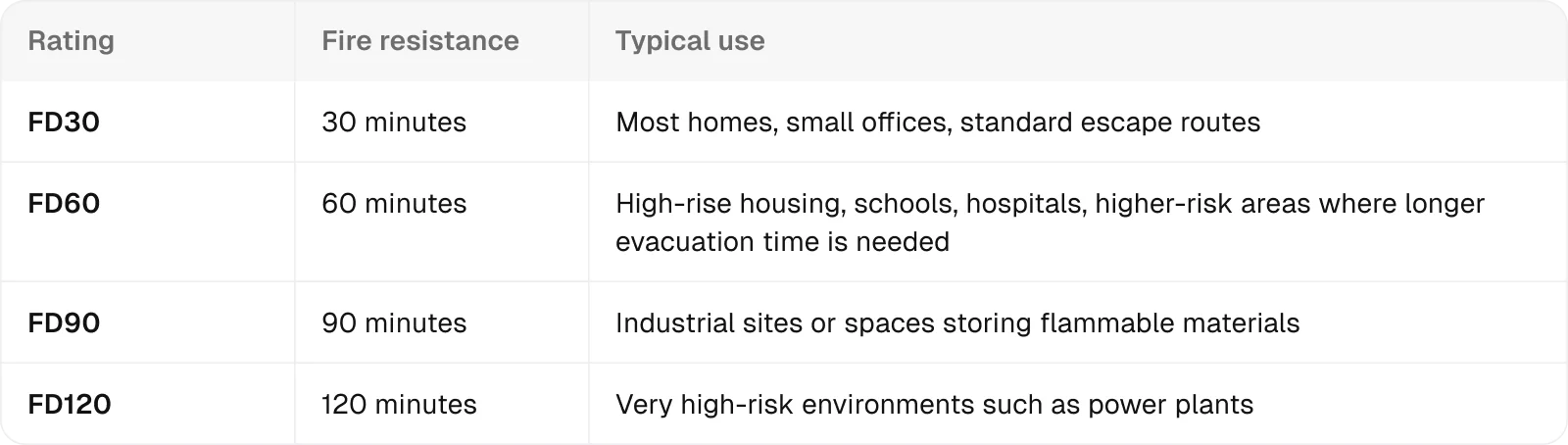

These doors primarily differ in how long they can hold back fire and smoke. In the U.K., this duration is shown by a fire door (FD) rating, which states the tested minutes of fire resistance.

Here’s a quick breakdown of the four most common ratings and where they’re typically used:

So, before you choose a door, make sure its rating actually matches the building, its layout, and the people using it.

And once the door is selected, the frame has to match it.

A standard frame won’t work for a fire doors installation. You need a frame that has the same fire rating as the door, the right thickness, and the correct seals for the doors to perform as tested.

3. What do the manufacturer’s instructions require?

Just as fire doors differ, so do their installation requirements.

The general process might look familiar, but the tested method, materials, and fixings can vary from one door set to another.

That’s why you must always follow the instructions supplied with the certified door, not a generic approach or what worked on a past job. And you must follow them word for word to keep the installation compliant.

4. Is the site ready for the fire door?

A fire doors installation can only start when the site is in the right condition. Key checks include:

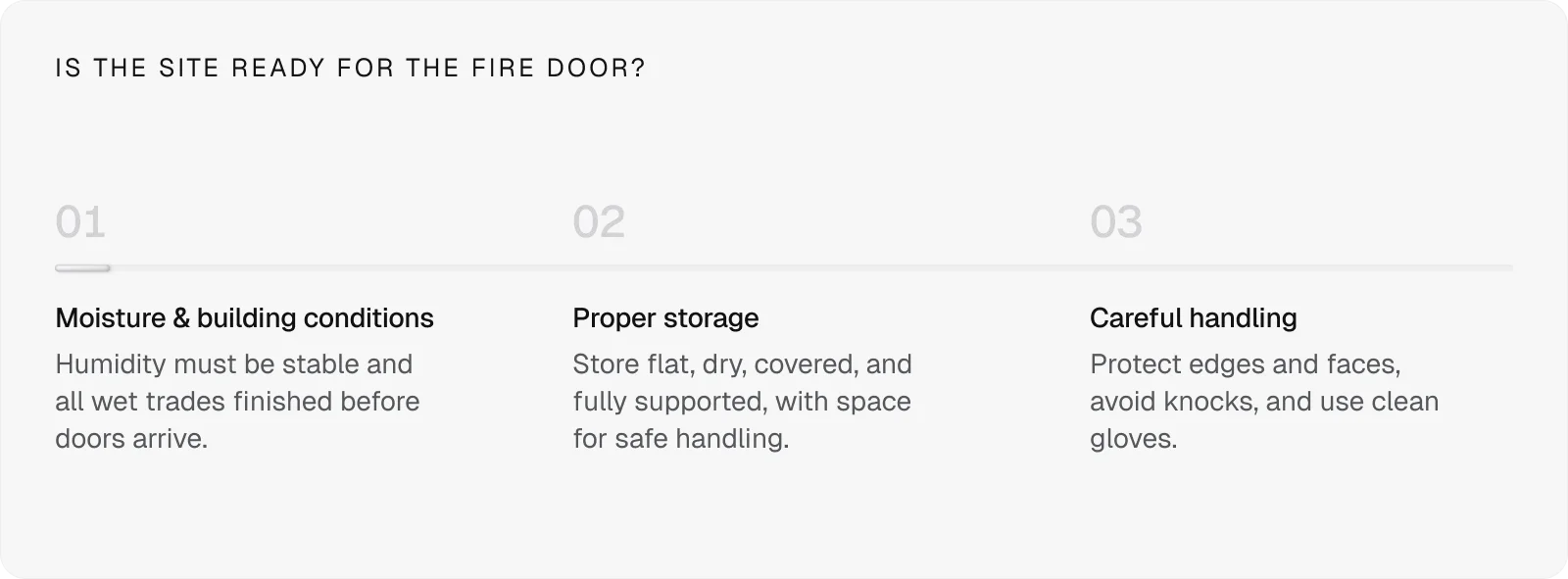

Moisture and building conditions: Only bring timber doors to the site when humidity is stable and the building is dry. The space should be past the “wet trades” stage, i.e., plastering, screeding, and forced drying must be finished.

Proper storage: Keep fire doors flat, dry, covered, and fully supported, with space to move and re-stack them safely.

Careful handling: Protect edges and faces, avoiding knocks, and use clean gloves to prevent marks or bruising.

Skipping these steps can cause warping, damage, or failed warranties long before the door reaches the frame.

5. Is the opening prepared and within tolerance?

The opening sets the foundation for the whole installation. If it isn’t square, level or sized correctly, even the best fire door won’t sit or perform as it should. That’s why the opening must be checked before any fixing begins.

As for the tolerance, each manufacturer sets its own, but it’s always tight.

For example, one common system allows no more than 10 millimetres of clearance on each side. So if the door frame measures 2,028 by 876 millimetres, the opening should be no bigger than 2,038 by 896 millimetres.

6. Do you have the right tools and materials?

A fire doors installation goes smoother and stays compliant when you have the right kit on hand before you start.

For tools, you’ll typically need:

Electric drill

Bubble level

Screwdrivers and a wrench

Spatula for applying sealant

Materials matter just as much, if not more.

In fact, one of the biggest mistakes in fire doors installation is using non-certified or incompatible components. Even a single uncertified hinge can void the door’s rating.

So, make sure you have:

Intumescent seals or gaskets

Fire-resistant sealant

Certified hinges, closers, locks, and latches

Any hardware the manufacturer specifies for that door set

Pro tip:

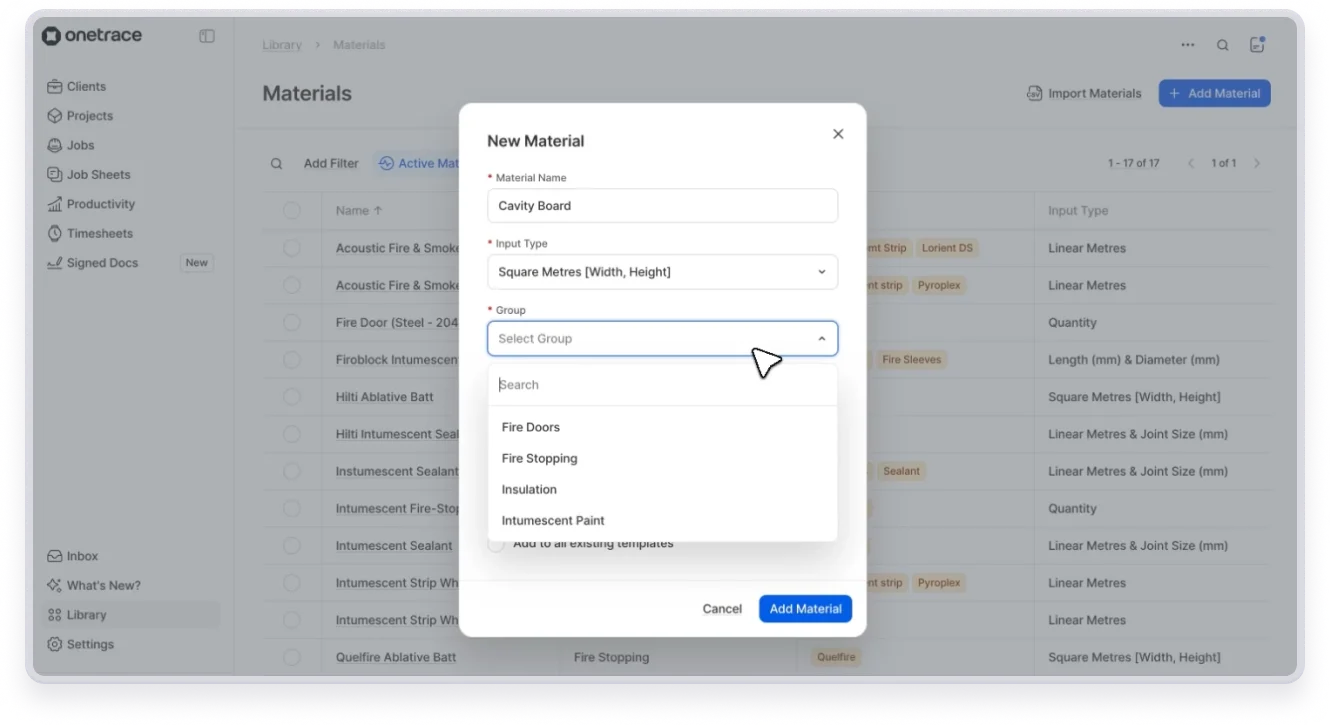

If you’re working across multiple sites, keeping track of the exact materials used and whether they’re approved for that door set can be a challenge.

That’s where fire protection software like Onetrace can help.

Onetrace lets you pre-configure fire protection components like intumescent paint, so every job stays aligned with the manufacturer’s spec.

This also helps with costing and traceability, which cuts out guesswork when it matters most.

7. Are all regulations and standards being met?

Before a fire doors installation begins, you need to confirm that the work complies with the Building Regulations and any other standards that apply to the project.

This includes checking the door set is certified for its intended use, confirming the supporting construction meets the tested detail, and making sure no alterations will invalidate the rating.

Do it right: 7 key steps in a fire doors installation

A fire doors installation should always be driven by the manufacturer’s manual. That’s where you’ll find the exact measurements, fixings, and tested details for that specific door set. What you’ll find here is an overview of the seven general steps most fire doors installations follow.

Step 1: Prepare the frame

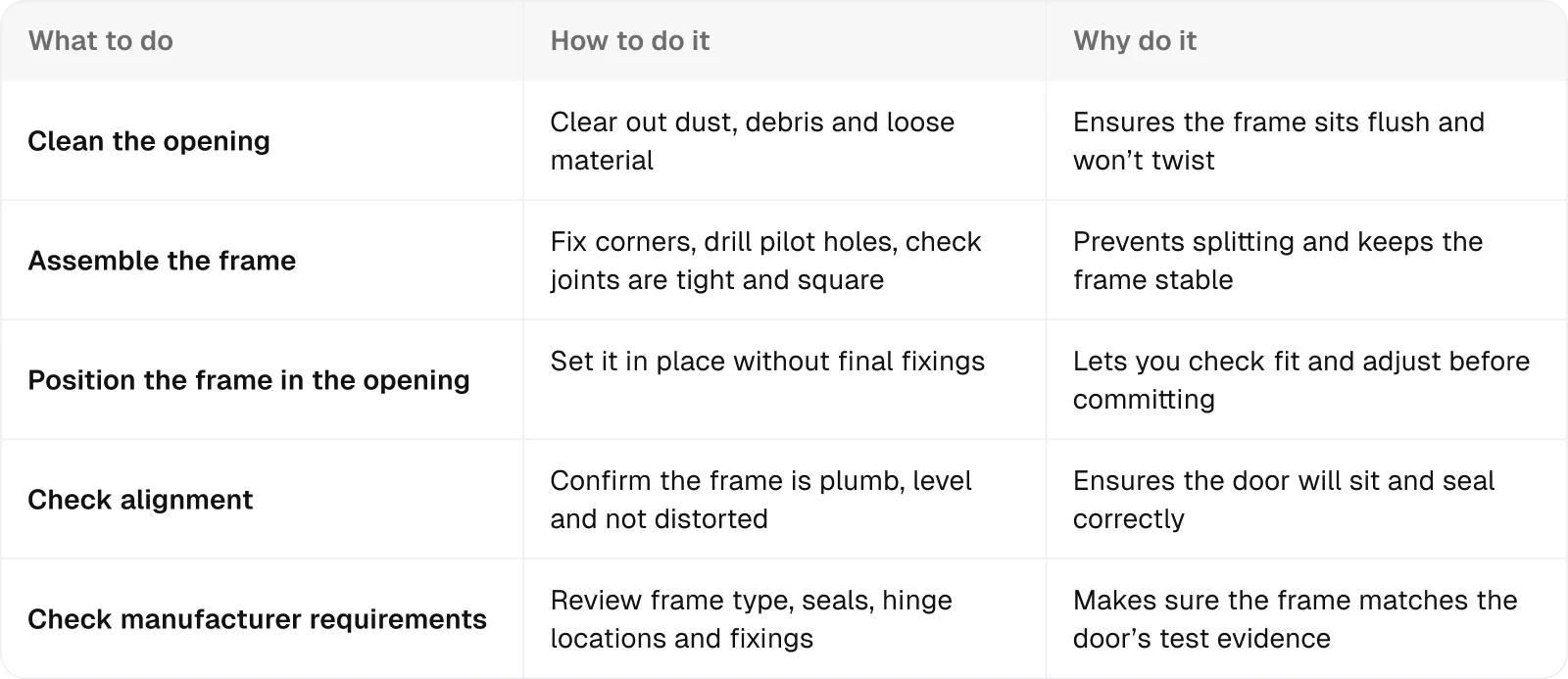

A fire doors installation starts with the frame. It needs to be fixed, aligned, and fire-stopped exactly as the manufacturer tested it. Work through each of the points below before the leaf goes anywhere near the opening:

This leaves you with a straight, supported, compliant frame ready for the door leaf.

Step 2: Hang and align the door leaf

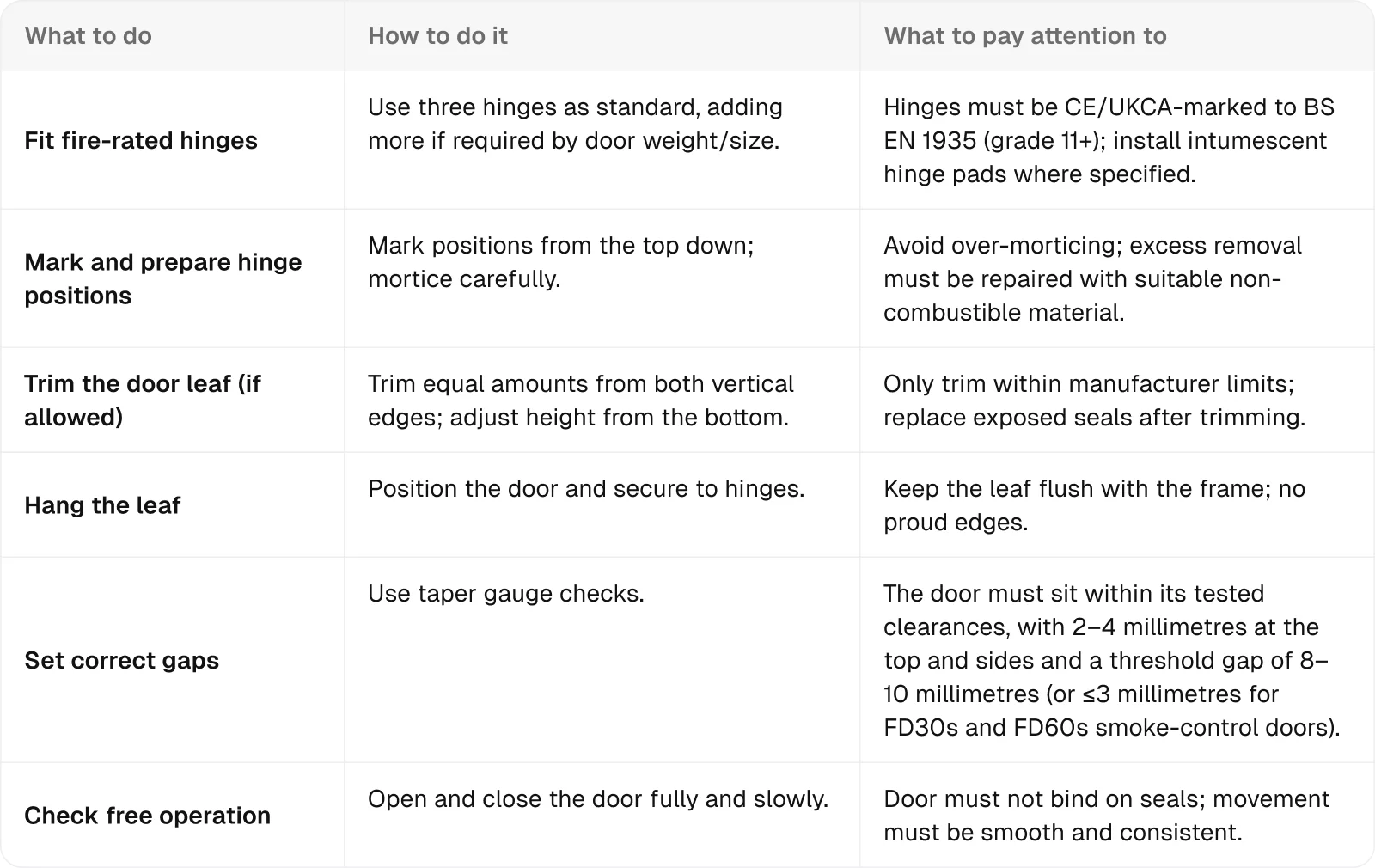

Next, you need to ensure the door leaf is fitted exactly as it was tested, using the right hinges, correct trimming, and precise gap control. Here’s what this means in practice:

This step leaves you with a leaf that operates smoothly and matches the tested fire-resistant configuration.

Step 3: Fix the frame securely

Once you’ve confirmed the leaf hangs correctly and the gaps are within tolerance, the frame can be permanently fixed.

This typically involves a series of substeps:

Remove the door leaf if needed so the frame doesn’t twist or distort during fixing.

Fix into masonry using plugs and screws with at least 50-millimetre penetration.

Fix into metal stud partitions by screwing through the stud and into timber fillets so the frame pulls up tight.

Re-hang the leaf once the frame is secure and operating gaps won’t shift.

Re-check all clearances to confirm nothing moved during fixing.

Make fine adjustments by adding packers behind hinges or recessing hinges; trim the leaf only as a last resort.

Check seal performance to confirm compression, blade, or brush seals meet the manufacturer’s contact requirements.

These substeps lock the frame in place without compromising the precise gaps and alignment needed for a compliant fire doors installation.

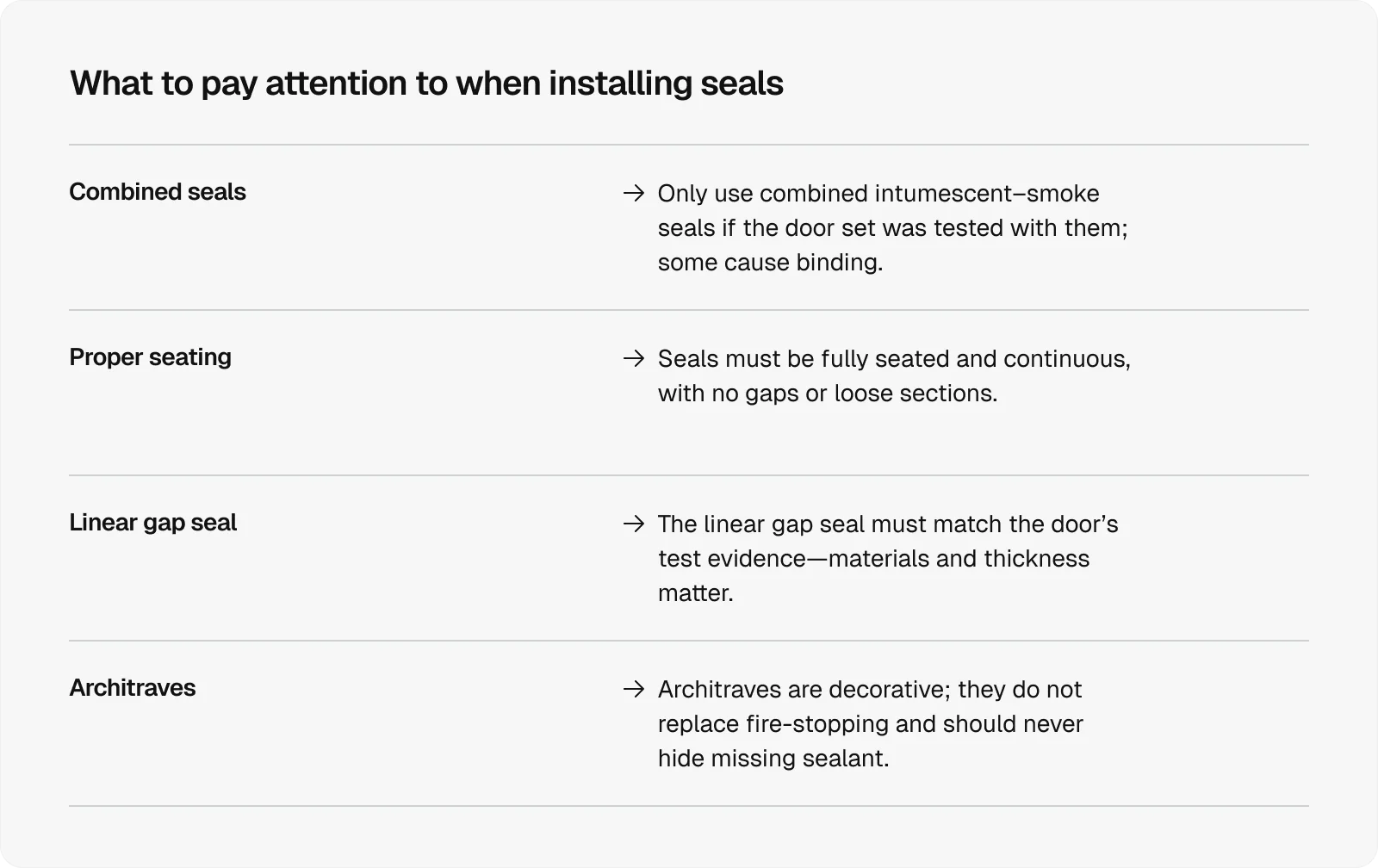

Step 4: Install seals and create the linear gap seal

Every critical gap—between the leaf, frame, and wall—must be sealed in the way the fire test requires. To achieve this, you’ll have to:

Fit intumescent and smoke seals exactly as specified in the manufacturer’s data sheet

Clean the grooves before installing seals so they sit tight and flush

Form the linear gap seal using tested materials (mineral wool, intumescent mastic, or approved foam)

Cap any insulation with intumescent mastic where smoke control is required

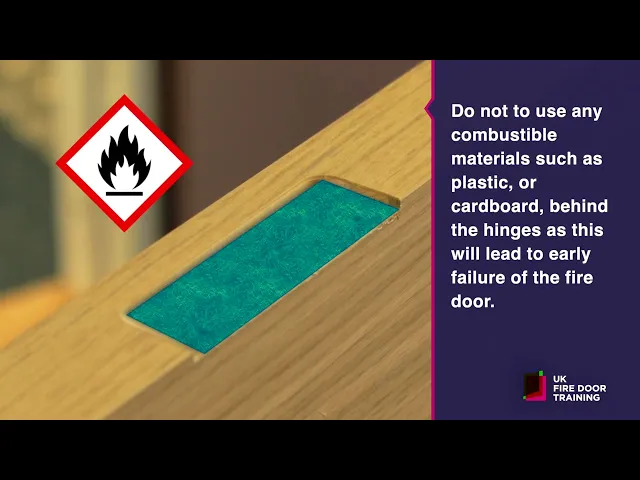

Trim back plastic packers and cover them with mastic

Fit architraves only after all fire-stopping is complete

The goal of these substeps is to protect the door’s fire performance by sealing the hidden gaps fire and smoke exploit first.

Step 5: Fit hardware and ironmongery

With the doors hanging correctly, the rest of the hardware needs to go in exactly as the manufacturer and certificate specify.

If you happen to over-cut anything, you should repair it with non-combustible materials—no fillers or shortcuts.

As for face-fixed items, such as signage and pull handles, they can be fitted later, once the risk of damage has passed.

Step 6: Install and commission the self-closing device

A fire door that doesn’t reliably close isn’t a fire door at all. That’s why you must correctly select, install, and test the closer to prove it can shut the door every time.

This includes:

Choosing a closer that suits the door’s location, weight, and opening direction

Checking that the closer is certified for that specific door leaf and configuration

Installing it using the supplied fixings and following the manufacturer’s template precisely

The testing phase includes checking whether the door closes fully from a 90-degree and 45-degree angle, as well as 75 millimetres from the latch—a key compliance point.

You’ll know you’ve successfully completed the step if the closer overcomes seal friction and latches firmly without bouncing or binding.

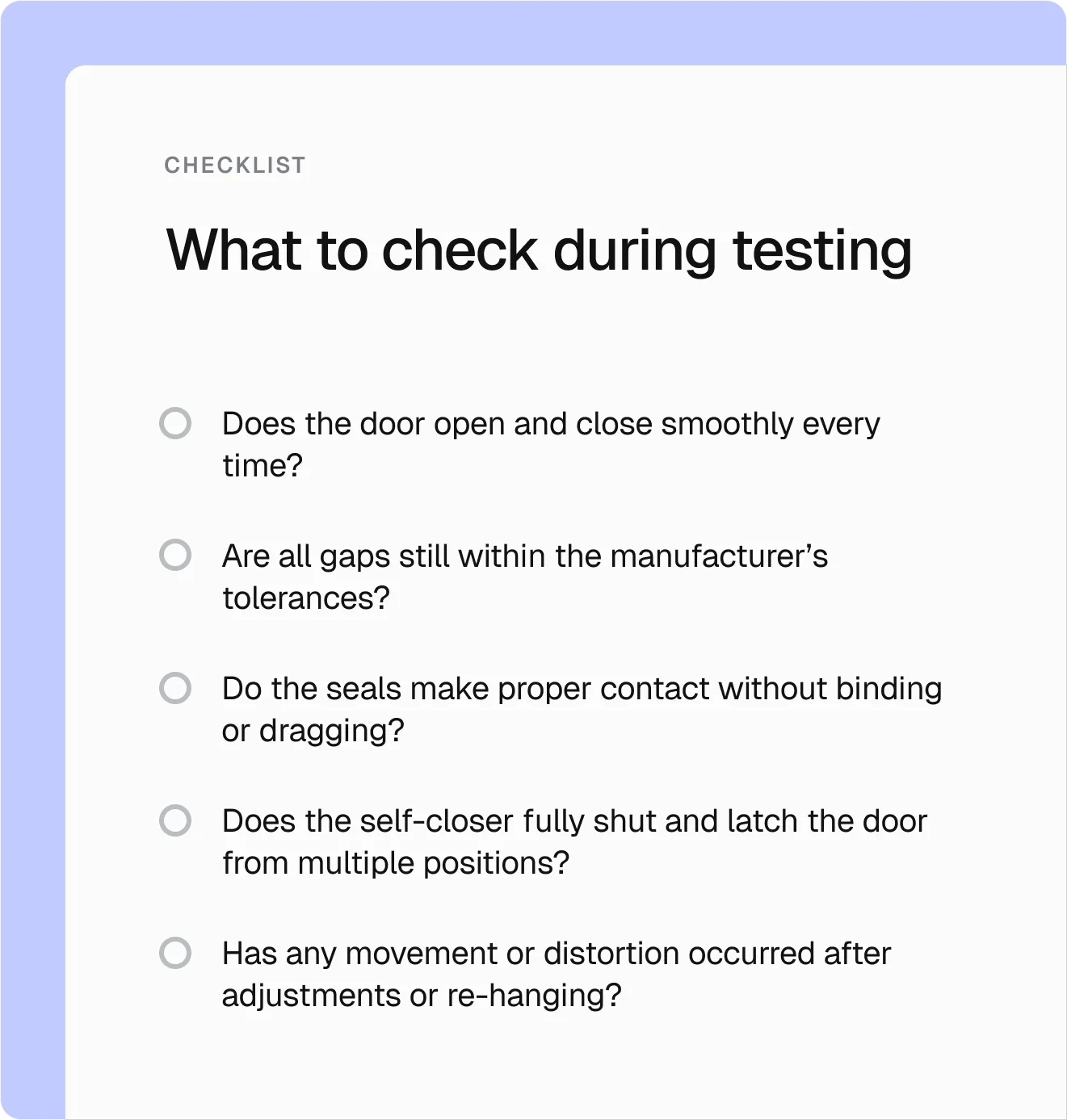

Step 7: Test, adjust, and finish

After ensuring the closer is properly fitted, it’s time to do that for the whole fire door system.

Here’s how:

Open and close the door repeatedly to confirm smooth, consistent operation.

Re-check every gap against the manufacturer’s tolerances.

Make sure seals aren’t binding or preventing the door from closing.

Test the closer again from multiple positions.

After testing, you can do the finishing touches, such as cleaning the door and tidying up any visible fixings.

Finish well: 2 actions to take after a fire doors installation

Even after the door is fitted and tested, the job isn’t over. These final two actions ensure the installation is properly recorded and the door stays compliant for the long term.

1. Tag and certify the fire door installation

Once the door is fully installed and adjusted, it must be formally certified.

To do so, you must submit evidence that the door and hardware match the tested specification. You’ll then receive the correct tags from the manufacturer, which you can fix to the door and frame to ensure full traceability.

2. Set up a maintenance and inspection routine

A fire door only stays compliant if it’s checked regularly.

That’s why you should set up periodic inspections, logging each result in the building’s fire protection documentation.

Pro tip:

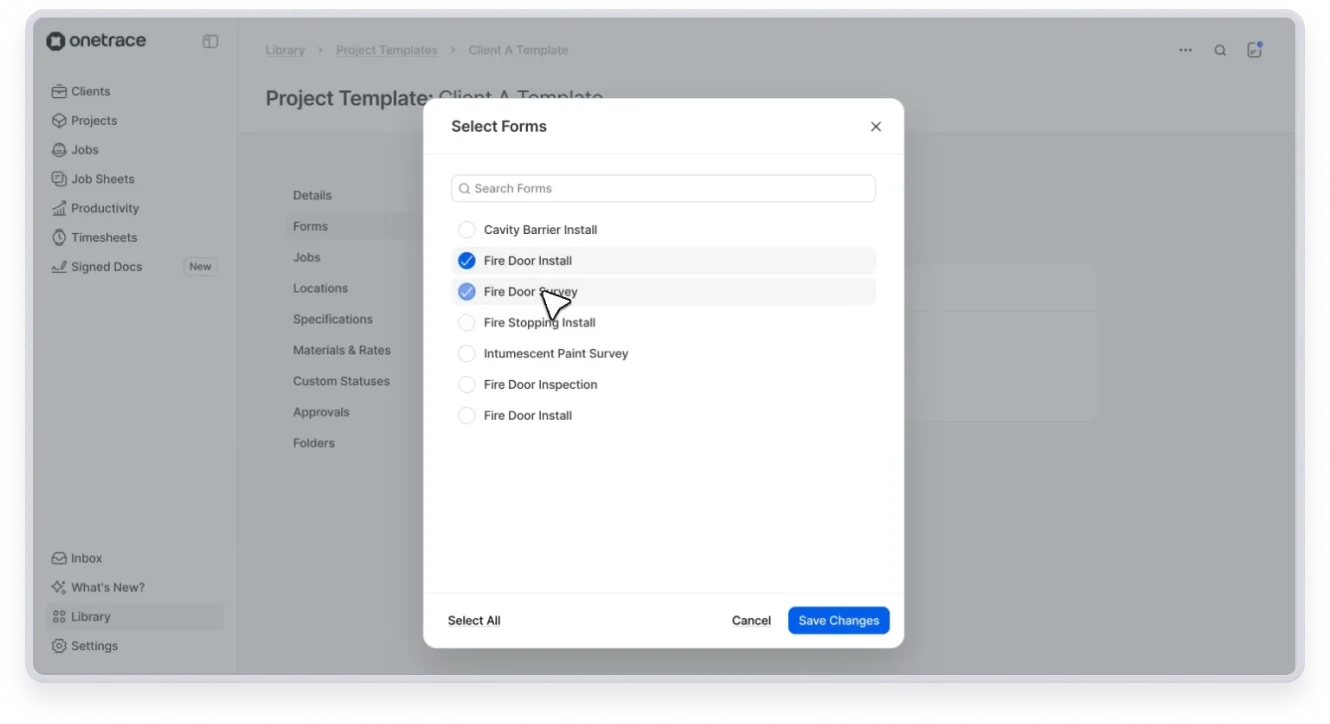

If you manage multiple buildings or clients, Onetrace Templates let you create repeatable inspection forms so every check captures the right details and follows the same standard, making ongoing compliance far easier to maintain.

The smarter way to manage fire doors installation

Given how many moving parts a compliant fire doors installation involves, relying on memory or paper trails isn’t enough. You need digital support that keeps every step clear, consistent, and traceable.

And that’s exactly what Onetrace provides.

With Onetrace, you can:

Standardise installations with pre-configured specifications, attributes, and tested materials

Store all fire door certificates, drawings and documents in one secure place

Label and track every door using QR codes for instant on-site verification

See real-time progress as installers log work directly from site

Map out the building using Site Manager to plan, sequence, and monitor installations floor by floor

It’s a practical way to keep installations consistent, evidence-backed, and easy to audit, no matter the size of the site or team.

If you’d like to see how Onetrace works in practice, book a personalised demo and we’ll walk you through it.

FAQ

How to correctly install a fire door?

By following the manufacturer’s tested method step by step. That means using the right frame, certified hardware, correct gaps, compliant seals, and a self-closer that actually shuts the door.

Can anyone install a fire door?

No. A fire door must be fitted by someone trained and competent, ideally backed by a recognised third-party certification scheme.

Marketing Team

@Onetrace

The Onetrace marketing team is passionate about sharing insights, ideas, and innovations that help construction businesses stay connected, compliant, and efficient. Combining industry expertise with a love for clear communication, we aim to deliver content that empowers professionals to work smarter and safer.